Robustly designed and manufactured for commercial and industrial washing applications, our heavy-duty, multi-

stage, closed loop treatment systems treats the wash water so it can be used continuously without any discharge to

the sewer or surroundings. Many companies choose to haul this water away, but a more efficient way of removing

this cost is by recycling and reusing the water.

Stage 1 – Solids Settling

Most commercial washing operations produce a lot of solids so the first stage of our filtration process is the solids handling system. We help you develop site-specific solutions to eliminate as many solids as possible before the water goes to the next stage of filtration. Solutions include sumps, basins, trenches or screening systems that are custom-designed sized to fit your facility restrictions, washing processes and maintenance procedures.

|

|

|

| Solids Handling Trench System | Solids Handling Basin System |

Stage 2 – Oils & Solids Separation

After the coarse solids settling, the water is processed through a multi-compartment stainless steel clarifier oil-water separator, which separates out smaller suspended solids, oil and water. In the first compartment, free oils float to the surface. In the second section, the stainless steel clarifying plates remove coarse amounts of oil and as much Total Suspended Solids (TSS) as possible. The angles of the non-clogging plates are 55° which allows solids to slide down the plates into the solids hopper, where they can easily be pumped out. Next, the water goes through our coalescing media which removes essentially 100% of all free and dispersed non-emulsified oils so the FOG effluent concentration can be as low as 5 ppm.

|

|

|

| SPT-10 Clarifier Oil Water Separator | SPT-30 Clarifier Separator with Pump & Control |

Stage 3 – Water Filtration, Odor Reduction & Polishing

After the clarifier oil-water separator, the water is pumped though several filtration steps including multi-media (sand, gravel, anthracite), blended activated carbon, polishing filter, and corona discharge ozone. These filters reduce odors and any contaminants to fewer than 10 microns in size, including emulsified oils, waxes, and other volatile organic compounds. Media, carbon, ozone and water storage volumes are typically customized to meet your particular application.

Closed Loop System Features

- Non-Ferrous Construction – Stainless Steel, PVC, Fiberglass

- Fully-Automatic, pre-wired

- Multi-Stage / Multi-Pass Filtration

- Clarifier Separator System

- Stainless Steel Clarifier Oil/Water Separator with 55° Hopper

- Advanced European coalescing media designed to remove oil droplets greater than 20 microns

- Electric or Air Diaphragm pump with controller

- Closed Loop Filtration System

- Automated Self-Cleaning Multi-Media and Carbon Fiberglass Filter Tanks

- Heavy-duty, high efficiency Re-Circulation Pumps

- Heavy-duty high efficiency Re-Pressurization Pumps

- Transfer pump to pump water from clarifier separator to system

- Heavy-duty Ozone System to control odors (up to 32 gms per hour)

- (2) Poly water storage tanks – UV Protected

- Sensors and interconnecting Schedule 80 plumbing

- NEMA-4X control panel

- PLC controller for automatic back wash operations

- All components mounted on heavy-duty stainless steel skid

Depending on the location, many options are available to maximize the efficiency of the wastewater treatment system including:

Optional Features

-

- Additional water storage tanks

- Bag filters

- Transportable equipment rooms

- Rain Diverter Systems

- pH control system

- TDS monitoring system

- Electric disk skimmers

- Automatic sludge dump systems

- Corrosion protection packages for high salt or corrosive applications

|

|

|

| CT-65 – 65 GPM Closed Loop Treatment System | CT-10 – 10 GPM Closed Loop Treatment System with Tanks & Separator |

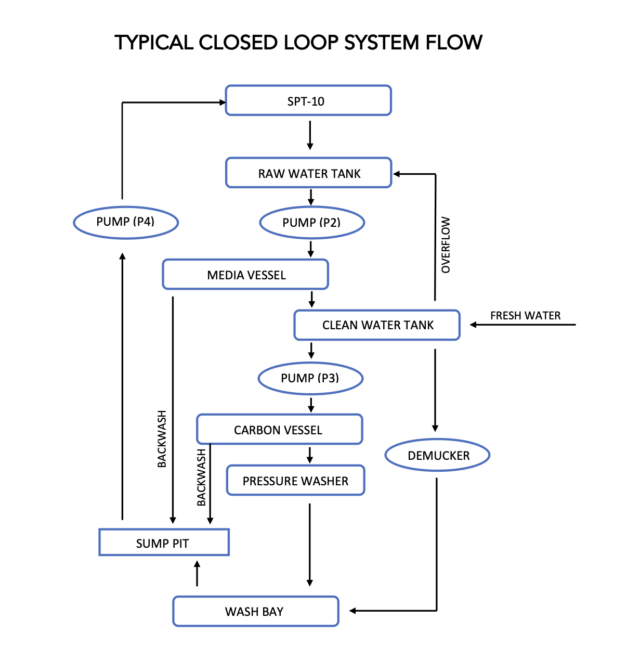

Typical Closed Loop System Flow Process

TYPICAL CLOSED LOOP SYSTEM SPECIFICATIONS

| MODEL | CT-10/10 | CT-35/20 | CT-65/50 | CT-100* |

| DESIGN FLOW RATE, GPM | 1-10 | 1-25 | 10-55 | 30-100 |

| COALESCING PLATE AREA, SF | 41 | 124 | 211 | 400 |

| COALESCING MEDIA, CF | 4 | 8 | 24 | 48 |

| CLARIFIER SEPARATOR SIZE, FT (WxLxH) | 3 x 7 x 5 | 3.5 x 8 x 6 | 4 x 10 x 6 | 5 x 11 x 7 |

| NON-EMUSIFYING INFLUENT PUMP, GPM MAX | 20 | 50 | 75 | 125 |

| MULTI-MEDIA, LBS | 300-500 | 500-1000 | 2500-2600 | 3700-4200 |

| ACTIVATED CARBON, CF | 4-15 | 10-40 | 20-40 | 40 |

| POLISHING FILTER, SET | 1 | 1 | 1 | 1 |

| RECLAIM RE-CIRCULATION PUMP, HP | 1.5 | 1.5 | 3 | 5 |

| RECLAIM RE-PRESSURIZATION PUMP, HP | 1 | 3 | 5 | 7.5 |

| DIRTY WATER STORAGE VOLUME, GAL | 500-750 | 500-1000 | 750-1500 | 1000-2500 |

| CLEAN WATER STORAGE VOLUME, GAL | 500-750 | 500-1000 | 750-1500 | 1000-2500 |

| OZONE SYSTEM, GRAMS/HR | 8-16 | 8-32 | 16-32 | 32 |

| RECLAIM CONTROL SYSTEM | PLC, Automatic, Manual or Off | |||

| RECLAIM PUMP FRAME SIZE, FT (WxLxH) (TANKS ADDITIONAL) |

4 x 6 x 6.5 | 4 x 8 x 8 | ||

| POWER REQUIREMENTS | 208 / 240 V 1 ph or 208 / 240 / 480 V 3 ph | |||

* LARGER CAPACITY SYSTEMS (200-1500 GPM) ARE AVAILABLE

APPLICATIONS:

- Commercial Trucking

- Locomotive

- Mining

- Marine

- Forklift

- Oil and Gas Drilling