We offer a complete line of high efficiency, stainless steel above ground oil water separators that will remove nearly all free and dispersed non-emulsified oil and settleable solids from the waste stream.

Oil Water Separators

The SPT Series Integrated Pretreatment Systems integrate an oil water separator with a clarifier to remove both floating oils and settlable solids.

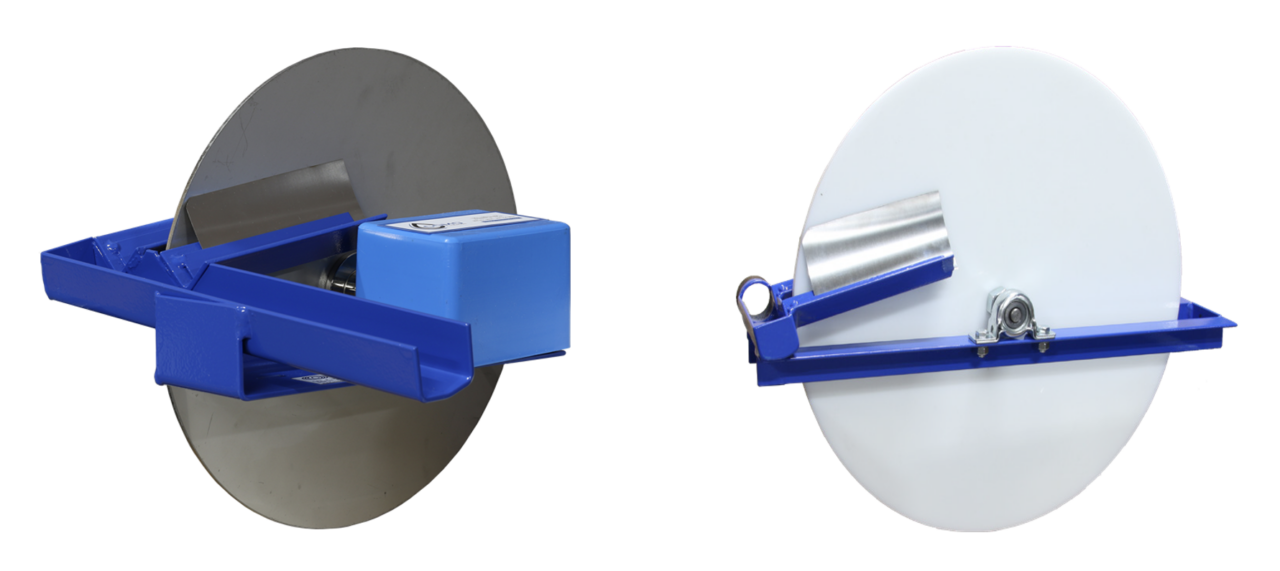

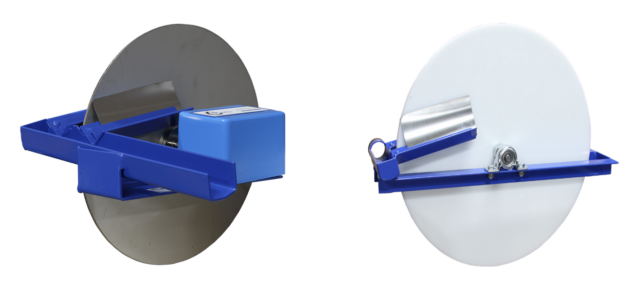

One of the most effective ways to remove floating oils from an oil water separator is with an electric 12” disk skimmer. Mounted on the side of the clarifier and/or coalescing compartments, the skimmer assembly consists of an oleophilic wheel that slowly rotates so that oils and sludge adhere to the wheel’s surface. A spring-loaded blade wipes the oil from surface of the wheel and discharges the oil into a steel trough connected to the oil storage tank.

The 115V disk skimmer motor is controlled by a simple control panel with a field-adjustable timer so that you can remove floating oils as often as necessary for your particular application.

Standard Features

- Front- or side-discharge trough

- High temp stainless-steel skimmer wheel for fluids up to 180°F

- 12-18-inch HDPE skimmer wheel for fluids up to 140°F

- 12-18-inch stainless-steel skimmer wheel for fluids up to 180°F

- 115 Volt, 7 RPM, shaded-pole motor & gear assembly

- Control with field adjustable timer

- Powder-coated skimmer frame and discharge trough

- Approximate dimensions: 14” W x 8” D x 12” H

- Approximate weight: 14

OPTIONS AVAILABLE

• Electric or air-driven pump and control systems

• Water polishing packs for strict effluent requirements

• Ozone systems for odor control

• Ozone systems for odor control

• Additional water treatment systems for differing site conditions

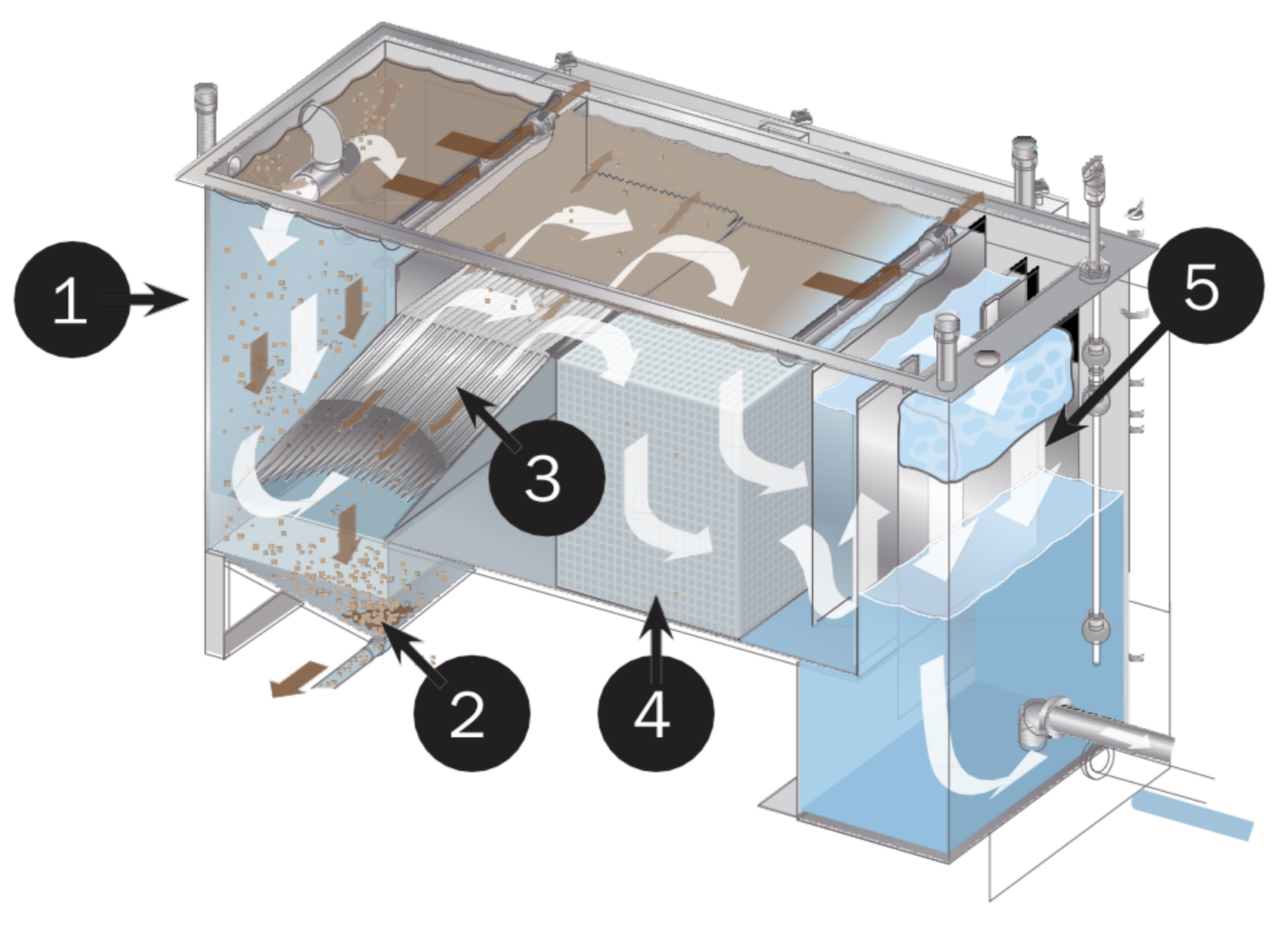

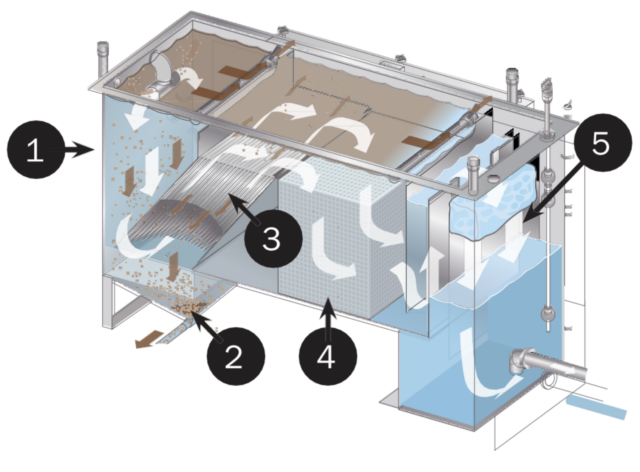

5 Stages Of Oil Water Separation Diagram

- The free oil (150 micron in size or greater) is separated in the inlet quiescent zone.

- The settleable solids will flow downward into the hopper section for removal.

- The suspended solids and dispersed oil will flow upward through the inclined plates

section, where most of the suspended solids will slide down the plates into the hopper. - The remaining suspended solids and dispersed oil will flow into the separation

compartment where the coalescing plates will separate the oil 30 micron or greater to

the surface for removal . - The flow of water will go over the overflow weir plate into the clean water compartment

and then discharge to the sewer.

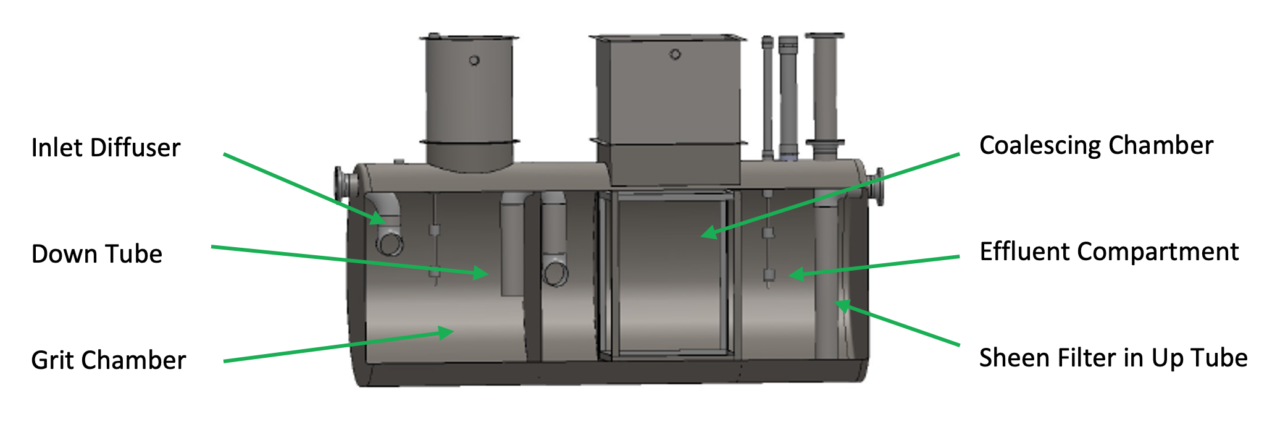

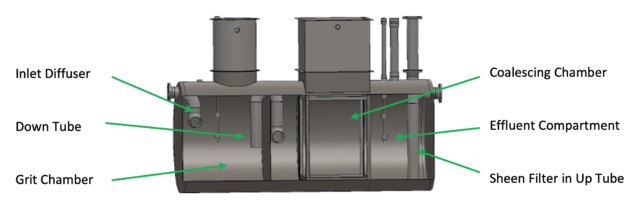

Our new solids settling below ground separator is ideal for any application with high concentration of solids and oil in water.

Most old conventional separators require long retention times, resulting in needlessly large units. They also have little in the way of solids settling. Our new innovative new design has both a much smaller footprint and a much higher removal efficiency for both oil and solids which lowers your total cost of ownership.

How it works:

To enhance separation, these separators contain an inlet diffuser, grit chamber/inlet compartment, down tube, coalescing/separation chamber, oil storage area, effluent compartment, and sheen filter.

- In the Grit Chamber, the inlet diffusor initially distributes the incoming water flow evenly over the cross-sectional area of the separator. The free oil (150 micron size or larger) is separated and the settleable solids are captured at the bottom.

- The suspended solids and dispersed oil then flow upward through the down tube in the Grit Chamber, and over to another diffusor in the Coalescing Chamber.

- The flow continues through the Coalescing Chamber where the coalescing plates will separate the oil droplets 30 micron size and larger up to the surface, and the remaining suspended solids will be captured beneath the coalescing plates.

- Finally, a removable Sheen Filter inside the up tube in the Effluent Compartment will remove carryover, smaller droplets of oil, and mechanical emulsions.

Performance Standards

- Utilizes patented, revolutionary, non- plugging coalescing plates which remove free oil droplets as small as 30 microns

- Performance guarantee based on influent characteristics

- Will achieve discharge of 5 ppm or less in accordance with CEN EN 858-1

- Warranted for (1) year on material and workmanship and (10) years against external corrosion

Below Ground Oil Water Separator Models

| Model # | Average Flow Rate (GPM) | Capacity

(Gallons) |

Inlet/Outlet (Inches) | Dimensions, D x L (Feet) |

| WB-QB-35-ES | 35 | 350 | 4 | 3.5 X 6 |

| WB-QB-55-ES | 55 | 550 | 4 | 4 X 6 |

| WB-QB-100-ES | 100 | 1000 | 6 | 4 X 10.75 |

| WB-QB-200-ES | 200 | 2000 | 6 | 5.3 X 12 |

| WB-QB-300-ES | 300 | 2500 | 6 | 5.3 X 15 |

| WB-QB-400-ES | 400 | 3000 | 8 | 5.3 X 18 |

| WB-QB-500-ES | 500 | 3800 | 8 | 6 x 17.5 |

| WB-QB-600-ES | 600 | 4000 | 10 | 6 x 18.75 |

| WB-QB-700-ES | 700 | 7000 | 10 | 8 X 18.67 |

| WB-QB-800-ES | 800 | 7000 | 10 | 8 X 18.67 |

| WB-QB-900-ES | 900 | 7000 | 12 | 8 X 18.67 |

| WB-QB-1000-ES | 1000 | 7500 | 12 | 8 X 20 |

| WB-QB-2000-ES | 1200 | 8500 | 12 | 8 X 22.5 |

| WB-QB-1500-ES | 1500 | 12000 | 16 | 10 X 20.75 |

| WB-QB-2000-ES | 2000 | 14000 | 18 | 10 X 24 |

| WB-QB-2500-ES | 2500 | 17000 | 18 | 10.5 X 26.5 |

| WB-QB-3000-ES | 3000 | 19000 | 20 | 10.5 X 29 |

Call Now to Speak with a Oil Water Separator Specialists – 1-800-453-8639!

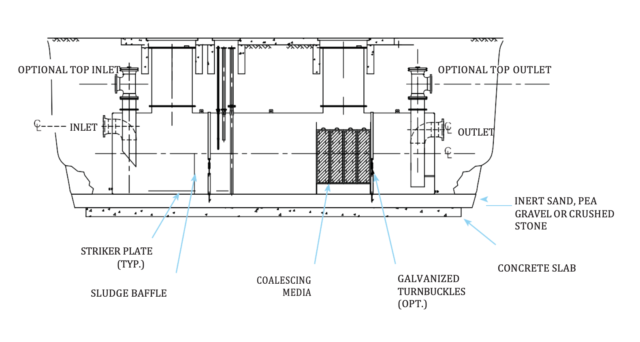

Our single wall or double wall below ground parallel, corrugated plate oil/water separators meet and exceed API 421 requirements, removing essentially 100% of dispersed non-emulsified oil droplets in the waste stream.

These separators are special purpose prefabricated parallel corrugated plate, cylindrical, gravity displacement oil water separators, containing an inlet compartment, sludge chamber, separation chamber, oil storage area and clean water compartment.

As shown below, the separation process if fairly simple. Wastewater flows into the inlet compartment. A baffle interrupts the flow and allows solids to drop out. Next the oil water moves into the separation chamber where our innovative media causes small oil droplets entrained in the water to coalesce into larger ones which then separate from the water and float to the surface. The clean water then travels into the clean water compartment through the outlet to the sewer.

Features

- Patented, revolutionary, non- plugging coalescing plates which remove free oil droplets as small as 20 microns

- Single wall or double wall construction with interstitial space for leak detection

- Rectangular access manhole with 3’ extension to service and maintain coalescing media

- Fittings for vent, oil pump out, sludge pump out, gauging and lifting lugs

- Exterior sandblasted and coated

- Will achieve discharge of 5 ppm or less in accordance with CEN EN 858-1

- Warranted for (5) years on material and workmanship and (30) years against external and internal corrosion

- Construction in accordance with UL58 and corrosion protection in accordance with UL1746

Options

- Internal coating for corrosion protection

- Grit chamber for high solids applications

- Hold down straps

- Leak and Level detection systems

Applications

- Parking Lots

- Re-fueling Facilities

- Marinas

- Military Installations

- Truck and Equipment Washes

How does it work?

Analysis

With these separators, we can provide analysis, which indicates that the separator will be provided with the required square feet of projected plate separation area to achieve the specified performance under laminar flow (i.e. Reynolds Number of less than 500) conditions. This service can include calculations signed by a registered professional engineer.

| Underground Oil Water Separator Specifications | |||

| Model # | Average Flow Rate (GPM) | Capacity (GALLONS) | Dimensions, D x L (FT) |

| WB-QB-342 | 35 | 350 | 3.5 x 6 |

| WB-QB-548 | 55 | 550 | 4 x 6 |

| WB-QB-1048 | 100 | 1000 | 4 x 10.75 |

| WB-QB-2064 | 200 | 2000 | 5.3 x 12 |

| WB-QB-3064 | 300 | 3000 | 5.3 x 18 |

| WB-QB-4064 | 400 | 4000 | 5.3 x 24 |

| Larger sizes available. | |||

Frequently Asked Questions

- How does the flow process work?

- How do you maintain an oil water separator?

- How does the oil separator remove the oil from water?

- What are the advantages to an oil water separator system?

- What is the difference between a clarifier oil water separator and an oil water separator?

- Why would you choose an above ground oil water separator vs. a below ground oil water separator?

Our standard media has vastly superior properties compared to the traditional media used in oil-water separators. These properties result in a more efficient and effective separation than that attained by traditional coalescing media.

- A larger amount of surface area per cubic foot of media allows for greater oil drop coalescence. This media has 132 ft2/ft3 surface area for oil droplets to contact. Other typical coalescing media have about 48 ft2/ft3 to 68 ft2/ft3.

- A more efficient first step separation reduces the need for a second polishing step. Our media removes 99.9% of oil droplets 20 microns in size and larger. This meets EPA Method 1664 Revision A and European Standard EN 858-1.

- An open design eliminates trapping of particles and subsequent clogging of water channels. Oil water separators with this media require fewer maintenance shut-downs and separates oil and water faster.

- Where higher-than-normal operating temperatures are required, our media outperforms its competitors. It works effectively in temperatures up to 212°F, versus a maximum temperature of about 120°F for competing media.

Give us a call at 800-453- 8639 for more information!

Even though the terms “Oil Interceptors” and “Oil Water Separators” are often used

interchangeably, they are very different systems.

Interceptors

Oil interceptors are typically used in low flow drain lines where small quantities of oils, sediment

and other liquid contaminants can be “intercepted”. These drain lines may come from variety of

facilities including covered parking garages, machine shops, service stations, and manufacturing

facilities.

Usually constructed of steel, fiberglass or plastic, interceptors are simple systems which include a

baffle plate, a solids bucket, and a separation area. As the water enters the interceptor, a baffle

plate reduces the flow and turbulence of the incoming water which helps to drop out some solids

and sludge.

A low flow rate and little turbulence permits the oils and other light density to slowly separate from

the water and rise to the top of the separation area. From there, relatively oil-free water is

discharged to the sewer.

Oil Water Separators

In comparison, Oil Water Separators have a far more sophisticated and efficient design. They are used in higher volume applications such as industrial wash operations, parking lots, re-fueling facilities and military installations where there is a potential for a much higher volume of water, oil, and contaminants.

In comparison, Oil Water Separators have a far more sophisticated and efficient design. They are used in higher volume applications such as industrial wash operations, parking lots, re-fueling facilities and military installations where there is a potential for a much higher volume of water, oil, and contaminants.

The standard oil water separator is a steel or stainless steel tank containing an inlet compartment, baffles system, sludge chamber, separation chamber with coalescing media, and clean water outlet chamber.

The water enters the inlet compartment where the oil separation process begins. Here, baffles slow down the water flow which causes some of the solids to drop out of suspension. Next, parallel corrugated coalescing media in the separation chamber cause the oil droplets in the water to coalesce together, and increase in size until they separate from the water. This coalescing media, with an internal structure of interconnecting channels, can remove essentially all free and dispersed, non-emulsified oils to an effluent concentration of less than 5 ppm – which is acceptable for discharge to most municipal sewer systems.

The water enters the inlet compartment where the oil separation process begins. Here, baffles slow down the water flow which causes some of the solids to drop out of suspension. Next, parallel corrugated coalescing media in the separation chamber cause the oil droplets in the water to coalesce together, and increase in size until they separate from the water. This coalescing media, with an internal structure of interconnecting channels, can remove essentially all free and dispersed, non-emulsified oils to an effluent concentration of less than 5 ppm – which is acceptable for discharge to most municipal sewer systems.

Above Ground Clarifier Oil Water Separator Flow Process

- The oil/water/sludge mixture enters the oil water separator

- The heavier sludge and particulates fall out of the fluid and are captured in the sludge hopper

- The oil and water mixture with lighter particulates travels up the inclined plates

- The inclined plates start to separate the mixture. Some oil rises to the top of the separator and the remainder of the particulates slide back down to the sludge hopper.

- The remaining oil and water mixture then moves through the coalescing media packs where the majority of the smaller oil particles attach to the media and combine together to form larger oil particles.

- These larger oil particles become so buoyant that they release from the media and travel to the top of the separator.

- As the oil volume in the separator reaches a certain level, the oil is drained to through piping to an oil storage tank.

- The clean water continues over the weir to the clean water chamber where it goes through a final polishing pack and out to the sewer.

WashBaySolutions.com offers a full line of oil and water separators that conform to the guidelines of API 421 for the removal of all free and dispersed non-emulsified oil and solids that settle from the waste stream. Get a Quote Today!

Oil Water Separator – Frequently Asked Questions

Please see a list of question and answers below related to our oil water separator products.

- How does the flow process work?

- How do you maintain an oil water separator?

- How does the oil separator remove the oil from water?

- What are the advantages to an oil water separator system?

- What is the difference between a clarifier oil water separator and an oil water separator?

- Why would you choose an above ground oil water separator vs. a below ground oil water separator?

- How to review and compare multiple oil water separators?

- What is the difference between Oil Interceptors vs. Oil Water Separators?

Problem: A car dealer moving into a new facility with a limited time lease. The property owner did not want them to cut concrete or substantially alter the property but the dealer needed to be able to wash dozens of cars per week onsite, contain the water and discharge it properly to the sewer.

Solution: For a complete wash system, we recommended installing a SPT-10 Clarifier Oil Water Separator System, a cold water pressure washer with a portable hose reel, and a portable wash containment pad. This allows them to wash as many cars as possible without any major modifications to the property. They will also be able to move the entire system to a new facility at the end of their lease. With their input, we helped them layout the system to maximize their space.

After installation of the pad, however, they noticed the concrete floor slope much slighter than originally thought and that the wash water was not moving off the pad well. This flat slope left his staff working in standing water and the SPT-10 not being able to process the wash water properly.

To improve this drainage issue, our staff developed a low cost under layer for the wash pad which created a slight slope for the water. We then installed this under layer and re-piped the in-take piping for the SPT-10 so the wash water flows freely. The general manager of the facility is very pleased with our systems and service.

Headquarters

WashBay Solutions International