Custom Control Systems

For over 30 years, we have provided custom engineered systems for a variety of industrial and commercial applications all over the world. All of these systems require some type of control system that has to be custom-engineered to meet our client’s specifications, maximize efficiency and reduce onsite monitoring. Some of our integrated control systems include:

Wash Bay Pumping & Treatment – Systems can control and monitor all reclaim and wash system components including pumps, tank level sensors, automatic valves, and filters. Lights and alarms can be added to help monitor water quality parameters and trouble-shoot components.

Rainwater Collection – Systems with digital display screens can monitor and control high and low collection tank levels, rainwater transfer pumps, valves and storage tank levels to ensure that all water collected will be available for use.

Wash Tunnel Entry and Control – These custom-engineered tunnel entry light systems feature industrial traffic fixtures affixed to the tunnel entry and ultra-bright LED illumination.

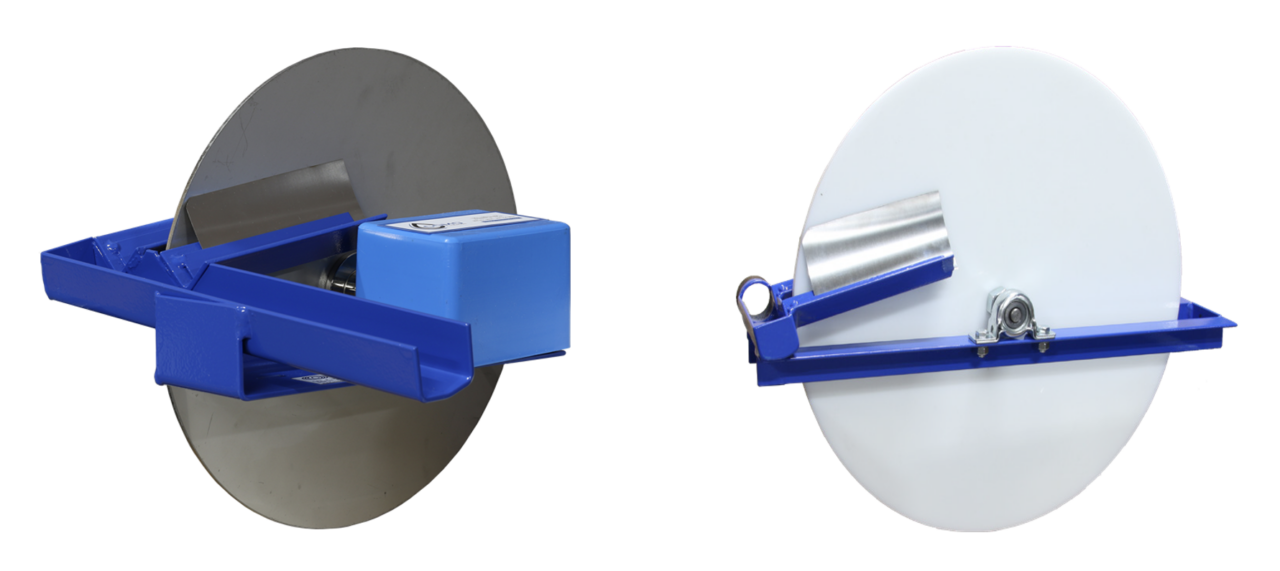

Photocell or Proximity Detection Systems – These systems are extremely rugged, with an industrial design, and heavy cast aluminum housings. They feature interchangeable logic modules and output devices.

pH Control – These systems adjust the pH of the water and are highly recommended if the pH of the water is either too high or too low from using industrial cleaning solutions. These systems normally include metering pumps, tanks, controllers and switches.

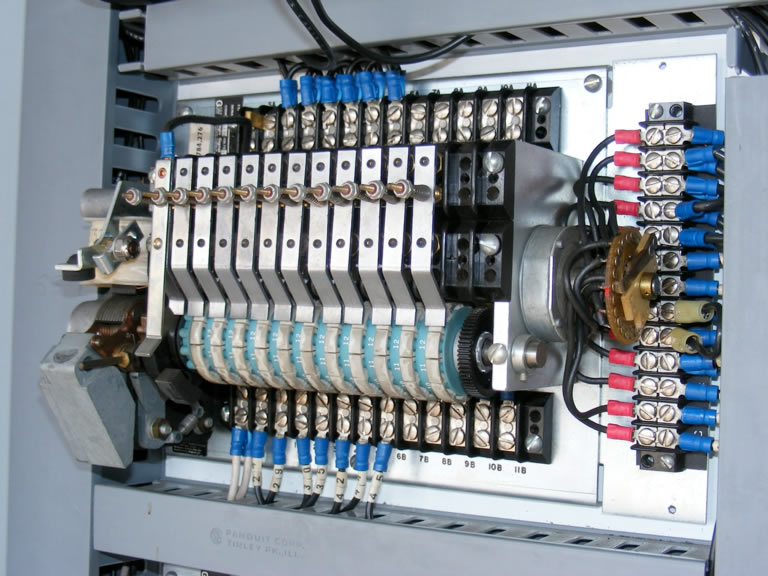

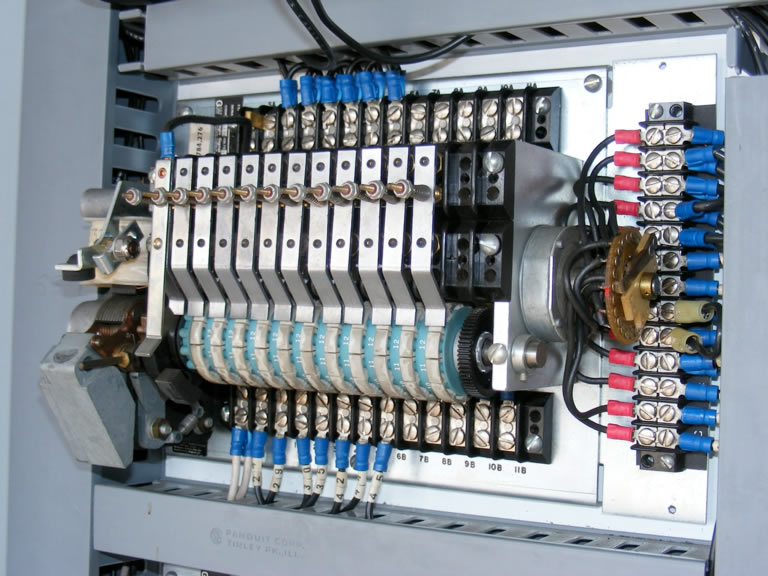

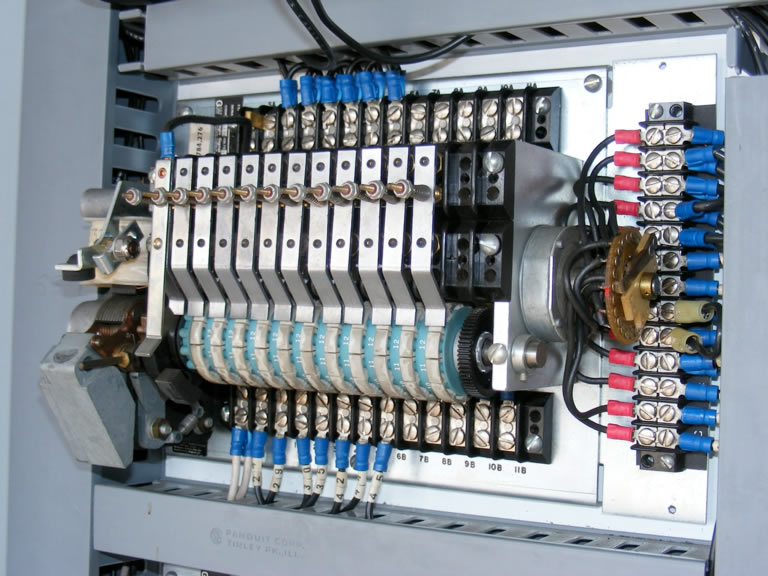

Our control panels are assembled with the highest quality electrical components, including Allen Bradley, Siemens, Eaton, and GE. System design tailored to interface with existing hardware and software to minimize compatibility concerns. Designs and assembly are focused on reliability and durability for continuous use in rail yards, bus depots, mining and oilfield service, and other heavy industrial applications. Features can include:

- Stainless Steel Master control panel

- NEMA 4X Rated

- UL Rating (Optional CSA Rating)

- Hands-Off-Automated (HOA) switches for all pumps

- Onboard digital display

- Modem for remote monitoring and control

- User-friendly monitoring software design to facilitate the system’s management

With each control system, we will provide detailed drawings and documentation packages with easy-to-follow descriptions, schematics, and wiring diagrams. Our engineers can also provide field installation, start-up and training for onsite personnel.

Call us at 1-800-453-8639 for help with customizing your control systems.