These complete Transportable Equipment Rooms (TER) are ideal for housing washing and reclaim equipment at sites without incurring any construction costs, delays, or permanent structures.

Controls Custom Systems

Our PH control system is designed to detect and treat water with pH levels outside a given range. A pH probe placed in the water continuously reads the pH of the water. When the pH is out of the desired range, the control panel will automatically signal the chemical dosing pump(s) to apply the correct amount of chemical additive to get the water back into the pre-set acceptable range.

Standard Features:

- Magnetic drive pump for circulation, mixing and discharging

- pH Probe

- Metering pump(s)

- NEMA-4X control panel

- Water management tank(s)

- Automated valve system for water transfer and discharge

- Weatherproofed to protect from water and environmental damage

Optional Features Available:

- Multiple pumps and tanks

- Integrated alarm systems

Custom designed for your application! Call Us Today 1-800-453-8639!

RDS-20 Rainwater Management System (Rain Diverter)

Many wash facilities do not have a roof over the wash pads so when it rains, storm water can flow through the pre-treatment system into the city sewers and overwhelm the system. To make sure that doesn’t happen, we have designed a simple, programmable rain diverter system (RDS-20).

The concept is fairly straightforward. When the system senses at least ¼” of rainfall, a controller turns on the pumps for a pre-set time to remove the floating oils and water from the wash pad through our pre-treatment system. This time is factory set for 15 minutes, but can be readily changed to suit field conditions.

After the first flush of rainwater with the contaminants are removed, the RDS then shuts down the system to prevent excess storm water from entering the tank and the sewer system. After the rain event, the RDS will reset to allow normal operation of the treatment system. If needed, the system can be manually overridden to allow washing operations during rain events.

Features

- Adjustable rain sensor

- Actuator and Jandy Valve

- Programmable controller with manual/automatic switch capability

Benefits

- Captures and directs first flush waters and contaminants

- Ideal for uncovered wash bays

- Can be designed to work with new or existing recycling systems

- Compact design can be mounted anywhere

- Can be configured to work with electric or air operated pumps

- Completely field programmable for rain sensitivity, pumping duration, and reset time.

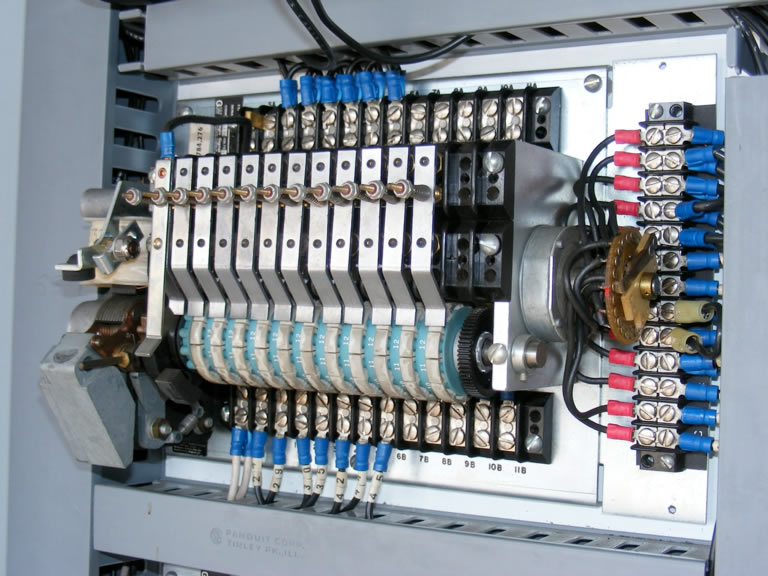

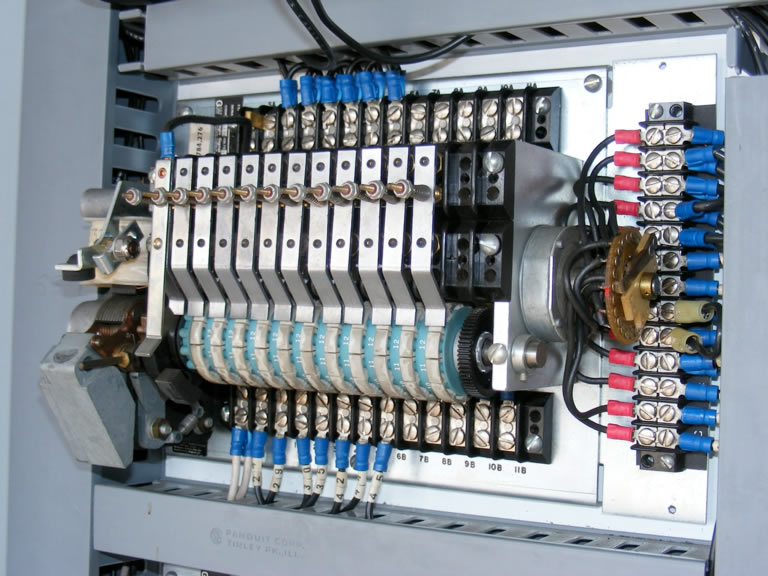

Custom Control Systems

For over 30 years, we have provided custom engineered systems for a variety of industrial and commercial applications all over the world. All of these systems require some type of control system that has to be custom-engineered to meet our client’s specifications, maximize efficiency and reduce onsite monitoring. Some of our integrated control systems include:

Wash Bay Pumping & Treatment – Systems can control and monitor all reclaim and wash system components including pumps, tank level sensors, automatic valves, and filters. Lights and alarms can be added to help monitor water quality parameters and trouble-shoot components.

Rainwater Collection – Systems with digital display screens can monitor and control high and low collection tank levels, rainwater transfer pumps, valves and storage tank levels to ensure that all water collected will be available for use.

Wash Tunnel Entry and Control – These custom-engineered tunnel entry light systems feature industrial traffic fixtures affixed to the tunnel entry and ultra-bright LED illumination.

Photocell or Proximity Detection Systems – These systems are extremely rugged, with an industrial design, and heavy cast aluminum housings. They feature interchangeable logic modules and output devices.

pH Control – These systems adjust the pH of the water and are highly recommended if the pH of the water is either too high or too low from using industrial cleaning solutions. These systems normally include metering pumps, tanks, controllers and switches.

Our control panels are assembled with the highest quality electrical components, including Allen Bradley, Siemens, Eaton, and GE. System design tailored to interface with existing hardware and software to minimize compatibility concerns. Designs and assembly are focused on reliability and durability for continuous use in rail yards, bus depots, mining and oilfield service, and other heavy industrial applications. Features can include:

- Stainless Steel Master control panel

- NEMA 4X Rated

- UL Rating (Optional CSA Rating)

- Hands-Off-Automated (HOA) switches for all pumps

- Onboard digital display

- Modem for remote monitoring and control

- User-friendly monitoring software design to facilitate the system’s management

With each control system, we will provide detailed drawings and documentation packages with easy-to-follow descriptions, schematics, and wiring diagrams. Our engineers can also provide field installation, start-up and training for onsite personnel.

Call us at 1-800-453-8639 for help with customizing your control systems.

Floating Oil Skimmers

Our triple-float oil skimmers are designed to free float on the water and remove non-emulsified oils from the surface. Constructed of stainless steel, they can be designed to be rigid or hinged to fit into small manhole openings in wastewater storage tanks.

Wall-Mounted Oil Skimmers

Our dual-float, wall-mounted oil skimmers are designed to remove non-emulsified oils from the surface of the water. Skimmers are constructed from stainless steel for corrosion resistance and sturdy enough for any application. The wall-mounted slide pipe allows the skimmer to float vertically but be kept close to the wall so it can be accessed easily. It can be built to accommodate any size sump.

Depending on the application, both skimmers can be custom-built for size and flow rate.

Our Wash Bay Solutions Stainless Debris Baskets are designed to both protect the equipment and help control costs associated with solids removal from wash bay sumps. The baskets are for washing applications with an average amount of solids. The baskets fit snugly into the sump and catch all solids from the wash bay before they reach the recycle systems. When the basket is full, personnel remove it and set it to the side to dewater. A second basket can then be placed into the sump and washing can continue. Once the sediment in the first debris basket is de-watered, it can be easily disposed of according to local enforcement agency regulations.

Applications:

- Heavy Equipment Washing

- Aircraft Maintenance

- Truck & Bus Washing

- Forklift Wash Facilities

- Military Bases

Benefits:

- Low Maintenance

- Heavy Duty Construction

- Impervious to Non-petroleum Materials

- Easy to Install

The baskets are constructed of stainless steel plates and stainless mesh. They come in standard sizes or custom sizes to fit into an existing sump. One or two handles on each basket make them easy to move around.

These complete wash systems are ideal for washing equipment and vehicles at sites without incurring any construction costs, delays, or permanent structures. Used on military bases, construction sites, and at any facility requiring transportability, these cost effective systems can be configured for a wide range of applications and up and running in a few weeks. Recycling wash water also eliminates EPA and local impact fees, reduces sanitary sewer costs, and water restrictions.

How Does the Re-Cyke® TWB System Work?

The complete system consists of a self-contained aboveground wash pad and an enclosed equipment room. The pad includes a 12” high ramped structure capable of handling up to 40 tons/axle and tracked vehicles, an integrated water collection system to isolate solids and divert liquids, and a solids wash-down feature. The enclosed equipment room sits adjacent to the wash pad and contains complete water recycling, high-volume demucking, and high-pressure washing equipment.

As vehicles are cleaned on the pad, the wash/rinse water collects beneath the pad and is transferred to the closed loop recycling system for treatment and reuse so there is no off-site discharging. The solids removed from the vehicle are automatically washed to a collection section for future removal and disposal.

STANDARD FEATURES:

Elevated Wash Pad with Ramp

- Totally Transportable in Modular Sections

- Designed for drive-through or in-out operation

- Heavy steel I-beam support framework

- Unique fluid/solid separation weirs

- High Volume Demucking Equipment

- Available in 10 tons/axle & 40 tons/axle

Enclosure:

- 40’ enclosure is steel, aluminum, or stainless

- Power panel, receptacles and lighting

- Automated fans/louvers or insulated with full HVAC system

- Pre-plumbed and wired

- Secondary containment for all fluids

Equipment Included in Enclosure:

- Complete closed-loop water recycling system

- Water management tanks with waste oil and solids storage

- PLC-controller with remote monitoring and SCADA capability

Hot or cold water pressure washer

- Optional high volume/low pressure Demucking system

- Non-chemical water dis-infectiing ozone generator

- Fully automated, requires minimal maintenance

- All equipment UL/CSA listed

TWB SERIES SYSTEM SPECIFICATIONS

|

MODEL |

TWB-5 |

TWB-10 |

TWB-20 |

TWB-35 |

| FLOW RATE |

1-5 gpm

|

1-10 gpm

|

5-20 gpm

|

5-35 gpm

|

| RE-CLAIM SYSTEM |

3/4 hp |

1 1/2 hp |

3 hp |

3 hp |

| INLET |

2” |

2” |

2” |

2” |

| OUTLET |

1” |

1” |

2” |

2” |

| WATER STORAGE TANK VOLUME |

500 GAL |

1000 GAL |

1000 GAL |

1500 GAL |

| PRESSURE WASHER |

4 GPM |

650 |

700 |

750 |

| KW (max.) |

1.8 |

2.0 |

3.0 |

3.0 |

| OZONE SYSTEM |

Up to 32 grams of ozone per hour |

|||

| CONTROL SYSTEM |

Automatic, Manual or Off |

|||

| ENCLOSURE |

40’ Steel Enclosure, pre-plumbed and wired Automated fans/louvers or insulated with full HVAC system |

|||

| POWER |

Power panel, receptacles and lighting 208 / 240 V 1 ph 208 / 240 / 480 V 3 ph |

|||