We offer a complete line of high efficiency, stainless steel above ground oil water separators that will remove nearly all free and dispersed non-emulsified oil and settleable solids from the waste stream.

featured

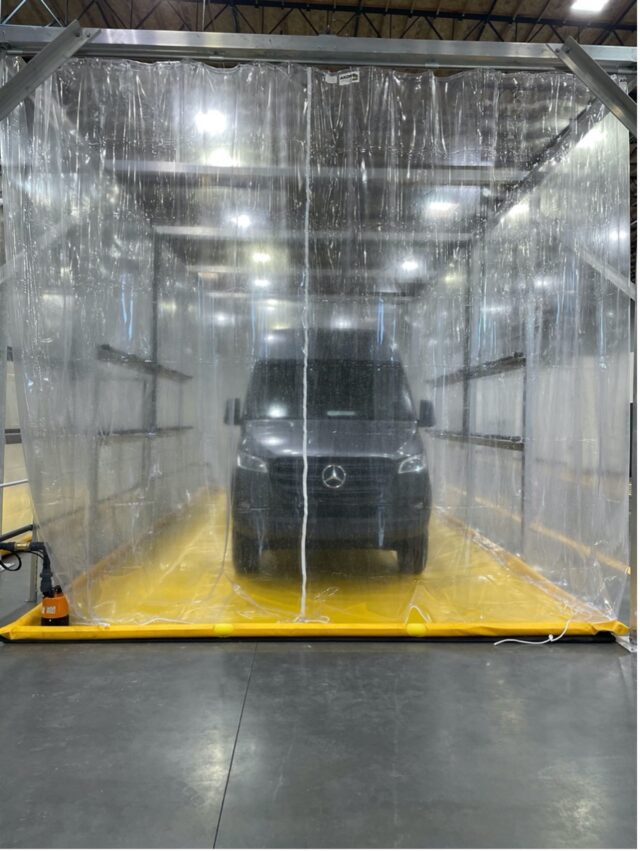

For clients who have to leak test vehicles to ensure that there has been no water intrusion after manufacturing or modifications, we have developed a complete leak testing system. Custom engineered to fit your facility and testing protocols, our water intrusion / leak testing systems consist of containment pads, test arches, a water supply system and a fully automated filtration system designed to remove contaminants from the test water so that it can be re-used for a period of time prior to disposal or discharge to the sewer. Designed for commercial and industrial applications, all features of the system are manufactured to insure superior performance and minimal operating requirements.

The containment system consists of a water containment pad constructed of steel or heavy-duty PVC.

Sized to fit your facility and test vehicle, these pads feature entrance and exit ramps and drive over and/or pedestrian grating, if desired. Custom-sized water-proof canvas canopies, PVC curtains or Fiberglass walls are installed on the pad to minimize overspray.

The leak test system is built to fit into the containment system so there is no overflow. Depending on the client’s needs, the leak test system will include multiple side and overhead spray arches, vertical spray posts, and undercarriage spray bars, positioned to provide optimal coverage. The spray test will last for a client-specified period of time and can be easily controlled by a driver with a remote start/stop key fob.

During the water intrusion / leak test, water is automatically pumped from the containment pad through an initial filter to remove any minor solids and contamination. From there, water is pumped into manifolded water management tanks. The tanks provide enough water storage to permit proper water balancing during the testing period and the water recovery time. The tank system is equipped with level switches to protect the pumps and to automatically provide for fresh water make-up due to evaporation or drive-off losses. From these tanks, water is pumped back to the test arches, when needed.

In most leak test applications, the contaminants are minimal so this pumping and filtration cycle can last a considerable amount of time. When the water becomes too contaminated to re-use, however, the water can be pumped out or processed through additional filtration and discharged to the sewer.

Containment Pad with Canopy/Walls –

- Either fiberglass covered steel or HD PVC containment basins

- Entrance & exit ramps

- Drive-over, galvanized grating, installed with supports

- Water-proof canvas canopy, PVC curtains or Fiberglass walls with supports

Leak Test System – designed for installation in containment pad

- Spray arches with PVC piping and Aluminum frames

- Entrance/Exit Spray posts with PVC piping and Aluminum frames

- Undercarriage spray floor spray bar with PVC piping

- Stainless steel fixed nozzles installed in PVC piping

Pumping & Treatment System- designed for installation adjacent to containment pad

- Typically 60 GPM Flow rate @ 40 psi – can be higher or lower to client specifications

- Non-Ferrous Construction – Stainless Steel, PVC

- Fully-Automatic, pre-wired, pre-plumbed

- UL listed custom control panel with relays and valves and level switches

- Remote start and stop, field adjustable run time

- Multiple water storage tanks with level sensors to receive water from basin

- Fresh-water make-up system to keep tanks filled

- Multiple pumps to circulate water from pad to arches and filtration system

- Initial filter system to catch particulate

Additional Options

- Final filtration system

- Oil water separator

- Spot free rinse

- Containerized equipment room

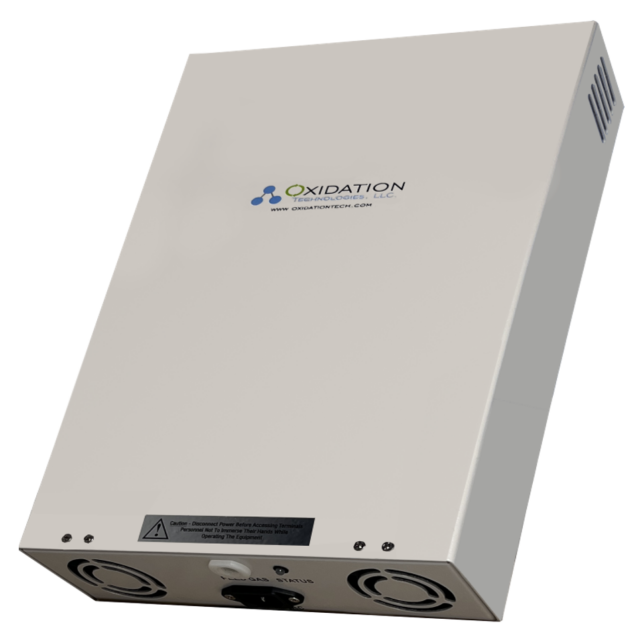

As an integral part of our closed loop wastewater treatment systems, our ozone generators eliminate odors and contaminates from the water and reduce operating costs by lowering freshwater usage and eliminating expensive chemical disinfectants and deodorants.

Depending on the application, our turnkey ozone generators house both an ozone generation cell and an oxygen concentrator or air dryer. Simply plug into electrical power and produce both oxygen and ozone from one unit. Compact, easy to use, and reliable, these systems will work in a variety of tough industrial applications.

Turnkey Ozone Generator with Air Dryer

- Produces up to 10 g/hr of ozone @ 4 l/min of oxygen at over 3% by weight

- Integrated Air dryer provides 8 LPM Dry Air for ozone generation

- Efficient ozone generation – high concentration ozone

- Air cooled Ozone Generator – no cooling water necessary

- Visual Flow-meter

- Adjustable ozone output

- Easy to install and operate

- Attachments to integrate into water reclaim system

- Power required: 120 or 220 VAC

- Compressed air required: 4 CFM

- Air dryer can provide air dried to 40 deg F dew point for more efficient ozone generation

- Removeable corona cell for easy cleaning or repair

Turnkey Ozone Generator with Oxygen Concentrator

- Produces 10-150 g/hr of ozone from 4-30 l/min of oxygen

- Integrated Oxygen Concentrator produces 4-30 l/min of oxygen

- Efficient ozone generation – high concentration ozone

- Air cooled Ozone Generator – no cooling water necessary

- Visual Flow-meter

- Adjustable ozone output

- Easy to install and operate

- Attachments to integrate into water reclaim system

- Power required: 120 or 220 VAC

- Compressed air required: 4-12 CFM

Optional features

- Stainless steel enclosure

- Remote on/off controls for system integration

- Internal compressed air

- Ozone analyzer

Robustly designed for construction and military applications, our portable wash racks provide an effective and economical alternative to a concrete wash pad. Each Portable Wash Rack has a flat base, sloped diamond tread surface and covered trenches to easily remove solids.

STANDARD FEATURES:

- No excavation required

- Designed to be surface-mounted

- Sides sloped to center

- Shovel trench making solids removal easy

- Diamond tread, grit impregnated non-slip surface

- Low profile entrance/exit ramps

OPTIONAL FEATURES:

- Splash Walls

- Canopy Covers

- Lights

- Entrance / exit ramps

- Drag conveyor for solids

- Undercarriage wash

ADVANTAGES:

Our “Low Profile” Wash Racks will accommodate a range of vehicles from high clearance large tanker trucks and mining equipment to low clearance trailers and forklifts. Projected useful life is 15-20 years.

Minimal site preparation, no excavation, quick installation, immediate use, low maintenance and portability are only some of the many advantages of our Wash Racks.

Give us a call for more product information – 800-453-8639

Our PH control system is designed to detect and treat water with pH levels outside a given range. A pH probe placed in the water continuously reads the pH of the water. When the pH is out of the desired range, the control panel will automatically signal the chemical dosing pump(s) to apply the correct amount of chemical additive to get the water back into the pre-set acceptable range.

Standard Features:

- Magnetic drive pump for circulation, mixing and discharging

- pH Probe

- Metering pump(s)

- NEMA-4X control panel

- Water management tank(s)

- Automated valve system for water transfer and discharge

- Weatherproofed to protect from water and environmental damage

Optional Features Available:

- Multiple pumps and tanks

- Integrated alarm systems

Custom designed for your application! Call Us Today 1-800-453-8639!

Robustly designed and manufactured for commercial and industrial washing applications, our heavy-duty, multi-

stage, closed loop treatment systems treats the wash water so it can be used continuously without any discharge to

the sewer or surroundings. Many companies choose to haul this water away, but a more efficient way of removing

this cost is by recycling and reusing the water.

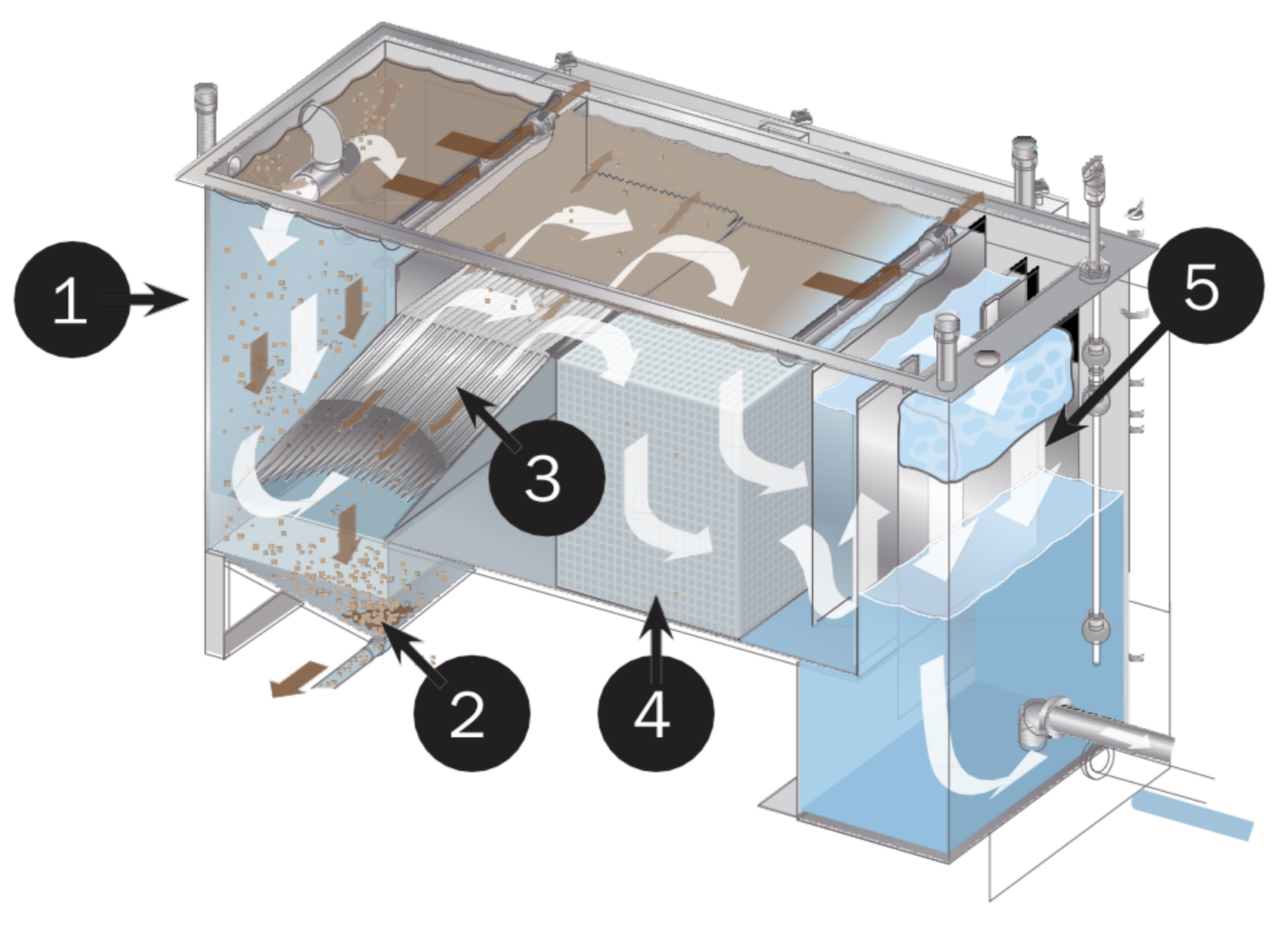

Stage 1 – Solids Settling

Most commercial washing operations produce a lot of solids so the first stage of our filtration process is the solids handling system. We help you develop site-specific solutions to eliminate as many solids as possible before the water goes to the next stage of filtration. Solutions include sumps, basins, trenches or screening systems that are custom-designed sized to fit your facility restrictions, washing processes and maintenance procedures.

|

|

|

| Solids Handling Trench System | Solids Handling Basin System |

Stage 2 – Oils & Solids Separation

After the coarse solids settling, the water is processed through a multi-compartment stainless steel clarifier oil-water separator, which separates out smaller suspended solids, oil and water. In the first compartment, free oils float to the surface. In the second section, the stainless steel clarifying plates remove coarse amounts of oil and as much Total Suspended Solids (TSS) as possible. The angles of the non-clogging plates are 55° which allows solids to slide down the plates into the solids hopper, where they can easily be pumped out. Next, the water goes through our coalescing media which removes essentially 100% of all free and dispersed non-emulsified oils so the FOG effluent concentration can be as low as 5 ppm.

|

|

|

| SPT-10 Clarifier Oil Water Separator | SPT-30 Clarifier Separator with Pump & Control |

Stage 3 – Water Filtration, Odor Reduction & Polishing

After the clarifier oil-water separator, the water is pumped though several filtration steps including multi-media (sand, gravel, anthracite), blended activated carbon, polishing filter, and corona discharge ozone. These filters reduce odors and any contaminants to fewer than 10 microns in size, including emulsified oils, waxes, and other volatile organic compounds. Media, carbon, ozone and water storage volumes are typically customized to meet your particular application.

Closed Loop System Features

- Non-Ferrous Construction – Stainless Steel, PVC, Fiberglass

- Fully-Automatic, pre-wired

- Multi-Stage / Multi-Pass Filtration

- Clarifier Separator System

- Stainless Steel Clarifier Oil/Water Separator with 55° Hopper

- Advanced European coalescing media designed to remove oil droplets greater than 20 microns

- Electric or Air Diaphragm pump with controller

- Closed Loop Filtration System

- Automated Self-Cleaning Multi-Media and Carbon Fiberglass Filter Tanks

- Heavy-duty, high efficiency Re-Circulation Pumps

- Heavy-duty high efficiency Re-Pressurization Pumps

- Transfer pump to pump water from clarifier separator to system

- Heavy-duty Ozone System to control odors (up to 32 gms per hour)

- (2) Poly water storage tanks – UV Protected

- Sensors and interconnecting Schedule 80 plumbing

- NEMA-4X control panel

- PLC controller for automatic back wash operations

- All components mounted on heavy-duty stainless steel skid

Depending on the location, many options are available to maximize the efficiency of the wastewater treatment system including:

Optional Features

-

- Additional water storage tanks

- Bag filters

- Transportable equipment rooms

- Rain Diverter Systems

- pH control system

- TDS monitoring system

- Electric disk skimmers

- Automatic sludge dump systems

- Corrosion protection packages for high salt or corrosive applications

|

|

|

| CT-65 – 65 GPM Closed Loop Treatment System | CT-10 – 10 GPM Closed Loop Treatment System with Tanks & Separator |

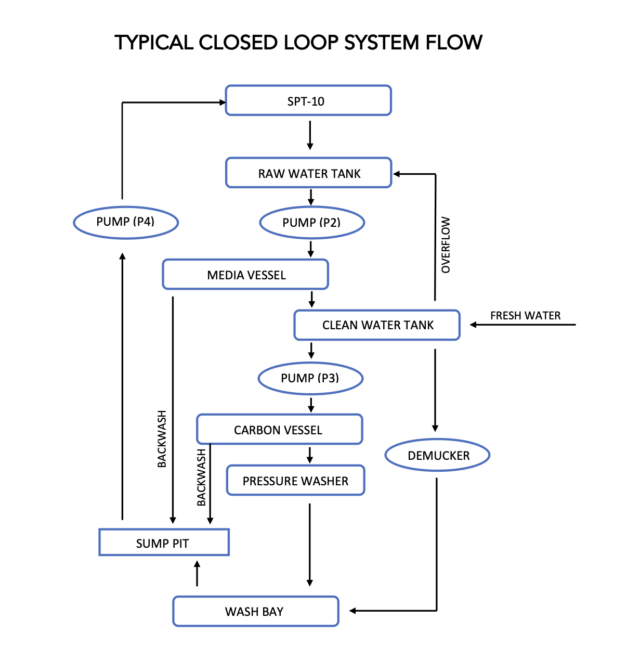

Typical Closed Loop System Flow Process

TYPICAL CLOSED LOOP SYSTEM SPECIFICATIONS

| MODEL | CT-10/10 | CT-35/20 | CT-65/50 | CT-100* |

| DESIGN FLOW RATE, GPM | 1-10 | 1-25 | 10-55 | 30-100 |

| COALESCING PLATE AREA, SF | 41 | 124 | 211 | 400 |

| COALESCING MEDIA, CF | 4 | 8 | 24 | 48 |

| CLARIFIER SEPARATOR SIZE, FT (WxLxH) | 3 x 7 x 5 | 3.5 x 8 x 6 | 4 x 10 x 6 | 5 x 11 x 7 |

| NON-EMUSIFYING INFLUENT PUMP, GPM MAX | 20 | 50 | 75 | 125 |

| MULTI-MEDIA, LBS | 300-500 | 500-1000 | 2500-2600 | 3700-4200 |

| ACTIVATED CARBON, CF | 4-15 | 10-40 | 20-40 | 40 |

| POLISHING FILTER, SET | 1 | 1 | 1 | 1 |

| RECLAIM RE-CIRCULATION PUMP, HP | 1.5 | 1.5 | 3 | 5 |

| RECLAIM RE-PRESSURIZATION PUMP, HP | 1 | 3 | 5 | 7.5 |

| DIRTY WATER STORAGE VOLUME, GAL | 500-750 | 500-1000 | 750-1500 | 1000-2500 |

| CLEAN WATER STORAGE VOLUME, GAL | 500-750 | 500-1000 | 750-1500 | 1000-2500 |

| OZONE SYSTEM, GRAMS/HR | 8-16 | 8-32 | 16-32 | 32 |

| RECLAIM CONTROL SYSTEM | PLC, Automatic, Manual or Off | |||

| RECLAIM PUMP FRAME SIZE, FT (WxLxH) (TANKS ADDITIONAL) |

4 x 6 x 6.5 | 4 x 8 x 8 | ||

| POWER REQUIREMENTS | 208 / 240 V 1 ph or 208 / 240 / 480 V 3 ph | |||

* LARGER CAPACITY SYSTEMS (200-1500 GPM) ARE AVAILABLE

APPLICATIONS:

- Commercial Trucking

- Locomotive

- Mining

- Marine

- Forklift

- Oil and Gas Drilling

Robustly designed for heavy industrial applications such as mining and oilfield services, WB-M-100/100 Monitor Washing System is great for cleaning large mining trucks, steel tracked vehicles or any vehicle where mud, clay, coal or dirt present a cleaning challenge.

Using recycled water, our revolutionary heavy-duty M-Series Monitor systems only use 100 gpm @ 100 psi, approximately 1/3 to 1/2 of the amount of water used in the traditional water cannons to easily and quickly clean large equipment.

These variable flow monitors with 360° horizontal rotation and 135° vertical rotation can be placed on rails on the mezzanines or strategically positioned within the wash bay, ensuring an effective wash for all of the hard-to-reach areas of the truck.

STANDARD FEATURES:

|

|

|

|

|

Give us a call for more product information – 1-800-453-8639!

Mining equipment washing applications are challenging for several reasons. Aside from the fact that they are very large, mining trucks are difficult to clean. So, for generations, people just used fire hoses to clean the trucks. This meant pumping hundreds of gallons of water per minute to knock off as much dirt and rocks as possible.

But we are changing that with new highly efficient systems that use less water. This is very important since most mine locations are often remote with no sewer connections and are ALSO adjacent to environmentally sensitive areas.

MINING TRUCK WASHING SOLUTIONS:

With our systems, washing is done with a limited amount of water. Typically, we recommend three separate systems: a cold water monitor, a cold water demucker and a heated electric pressure washer.

Water Cannons / Monitors – Cold water monitors placed on rails or stands on the mezzanines initially wash the side and top of the trucks. The monitors will have 360° horizontal rotation and 135° vertical rotation, -45° to +90°. The monitors have variable flow nozzles that typically provide 100 GPM of water @ 100 PSI (378.5 LPM @ 689kPa). Typically, only one monitor is used at a time.

Demuckers – Demucking station reels are placed on the wash bay floor on either side of the wash bay. The hand-held demuckers can provide 20 GPM of water @ 1000 PSI (75.7 LPM @ 6895 kPa). By moving around the truck, operators can remove any dirt and solids missed by the monitors. Typically, one or two demuckers are used at a time.

Both the monitors and demuckers have remote start/stop control panels to permit an operator to control the pump operation. These NEMA-4X control panels include a momentary start switch and emergency stop switch; the start switch initiates a timer in the main control panel to run the pump for a pre-set time period to prevent unintended continuous operation.

Heated Pressure Washers – A heated pressure washer is used for a final wash, degreasing wash or de-icing. Pressure washer reels are be placed on the wash bay floor on either side of the wash bay. Typically, the pressure washer provide 5.4 GPM of water @3000 PSI (20.4 LPM @ 20684 kPa) with 72KW of heat. These systems use a trigger gun activated start/stop with time-delayed shut down.

MINING TRUCK WATER TREATMENT SYSTEMS

The first step in water treatment is solids handling so we help design the best solids settling basin for your particular facility. Water treatment is typically done with a CT-Series wash water reclaim system with closed loop recycling system, capable of processing about 100 GPM (378.5 LPM). The system includes a clarifier oil water separator, fully automated solids filtration, activated carbon (GAC) filtration, an ozone generator, and a polishing filter to treat the water and prevent odors.

The system is designed to be completely closed-loop with no external discharge. It constantly re-circulates water from the raw water tank through the media filter, ozone injector and to the clean water tank. The process generally flows as follows:

- The water from the wash pad floor initially flows into a two compartment solids collection sump which will be cleaned out periodically. From the sump, a positive displacement pump will pump the water to a clarifier oil water separator which removes suspended solids, oils and greases.

- From the clarifier separator, water is pumped to a tank and then pumped to the recycle section of the CT filtration system where the water is filtered through a sand media filter, ozonated to reduce odor, and then directed to a second tank. Water is constantly circulated from Tank 1 through the CT Filtration system, and then to Tank 2. The cold water monitor system and demuckers are fed from Tank 2.

- In the secondary filtration section of the CT system, the fluid is then routed through tertiary filtration that includes a carbon bed to remove emulsified oils and soaps and a final filter to remove solids down to 20 microns. When the pressure washer requires water, the pump will provide cleansed, treated water for usage.

- An automatic backwash in the CT system occurs daily to prevent the sand and carbon filters from plugging with fines.

All equipment can be installed in a complete 40’ long transportable equipment room (TER-40HC). This will save on building and installation costs, provide protection from the weather and allow you to move the equipment to a different facility if the need arises.

Mirachem is a water based cleaner/degreaser that has been formulated using Mirachem’s proprietary emulsifying technology coupled with non-hazardous cleaning ingredients. This unique combination provides a cleaner/degreaser that can safely remove oil, grease, carbon and other organic deposits from all types of surfaces while meeting federal, state and local air pollution and wastewater regulations.

Mirachem is a highly concentrated, environmentally safe cleaner engineered to lift oil, grease and road film from surfaces to be rinsed away with water. This sudsing formula is designed to increase dwell time and prevent re-depositing. It can be used on most surfaces including stainless steel, plastic, aluminum, paint and automotive wax finishes.

Safety Attributes

- Contains no acids, phosphates, alkalines, chlorides, ethylene glycol ethers or other hazardous ingredients

- pH balanced

- Non-toxic

- Non-caustic and non-corrosive

Industry Cleaning Applications

- Military and Civilian Aircraft

- Ground Transportation Equipment

- Trucks and Heavy Equipment

- Bus Washing

- Locomotive Washing

- Boats, marine engines, bilges, decks

- Automobiles, light trucks, automotive engines, parts, brakes

- Tanker and tank washing

Mirachem 500 Cleaner / Degreaser

Mirachem 500 is a water-based cleaner/degreaser that has been formulated to safely remove oil, grease, carbon and other organic deposits from all types of surfaces while meeting federal, state and local air pollution and waste water regulations. Mirachem 500 Cleaner / Degreaser is an excellent alternative to hazardous solvents and chemicals.

Mirachem 500 Approvals/Certifications

- Boeing D6-17487 Revision J – For exterior and general cleaners.

Boeing D6-17487 Revision K For exterior and general cleaners - ISO 9001:2015 QMS Certification

- ASTM G122 Standard Test Method for Evaluating the Effectiveness of Cleaning Agents.

- NSF-8A – NSF Approved for Category A-8 Degreaser

- Meets stringent environmental regulations for air quality, such as VOC content and VOHAPS, and wastewater systems, including Total Toxic Organics (TTO).

Mirachem® Pressure Wash

Mirachem® Pressure Wash is a highly concentrated, yet environmentally safe cleaners engineered to lift oil & grease, road film, and other environmental soils from surfaces to be rinsed away with water. This sudsing formula is designed to increase dwell time and prevent re-deposition on surfaces to be cleaned. Mirachem Pressure Wash can be used on most every surface and is safe for both interior and exterior uses.

Mirachem Cleaner Degreasers

| Product | Uses | Dilution Ratios | Size | Part Number |

| Mirachem 500 | Most surfaces including stainless steel, plastic, aluminum, chrome, fiberglass, paint and wax finishes. | 20:1 Light Pressure washing

10:1 Heavy Duty Pressure Washing 4:1 to Full Strength Hand Wipe, Brush & Bucket |

55 gallon drum | M-500-D |

| 275 gallon tote | M-500-T | |||

| Mirachem Pressure Wash | Most surfaces including stainless steel, plastic, aluminum, chrome, fiberglass, paint and wax finishes. | 19:1 Light Pressure washing

4:1 Heavy Duty Pressure Washing |

55 gallon drum | M-PW-D |

| 275 gallon tote | M-PW_T |

OPTIONS AVAILABLE

• Electric or air-driven pump and control systems

• Water polishing packs for strict effluent requirements

• Ozone systems for odor control

• Ozone systems for odor control

• Additional water treatment systems for differing site conditions

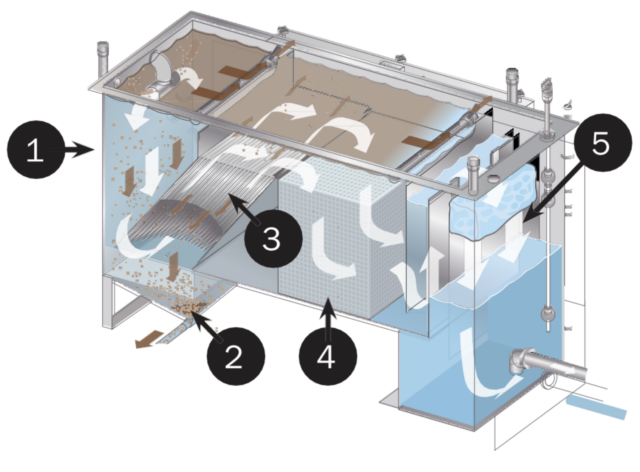

5 Stages Of Oil Water Separation Diagram

- The free oil (150 micron in size or greater) is separated in the inlet quiescent zone.

- The settleable solids will flow downward into the hopper section for removal.

- The suspended solids and dispersed oil will flow upward through the inclined plates

section, where most of the suspended solids will slide down the plates into the hopper. - The remaining suspended solids and dispersed oil will flow into the separation

compartment where the coalescing plates will separate the oil 30 micron or greater to

the surface for removal . - The flow of water will go over the overflow weir plate into the clean water compartment

and then discharge to the sewer.