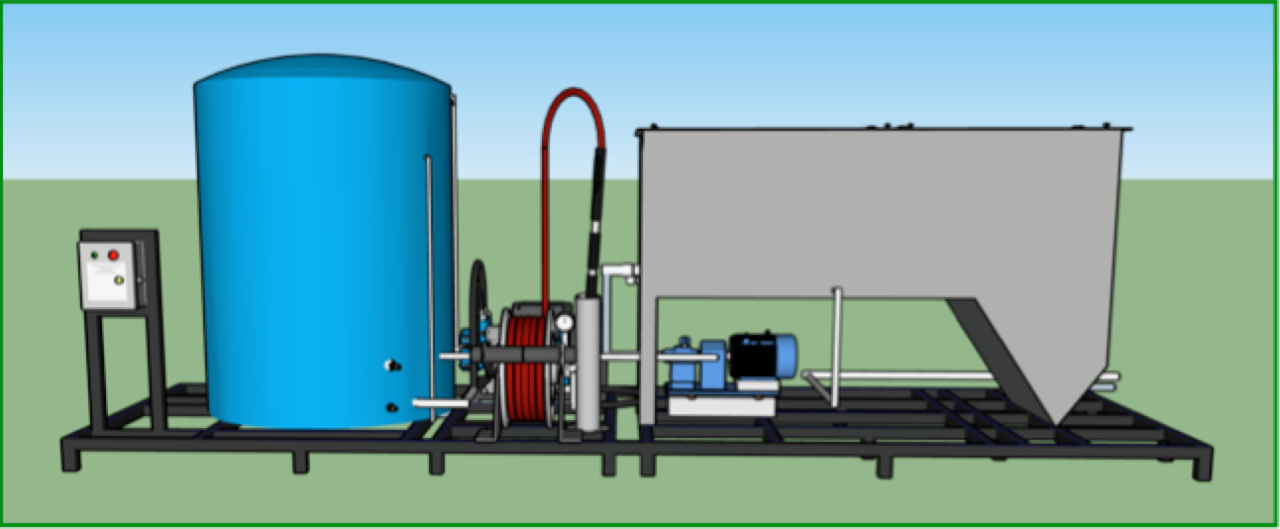

For over 30 years, we have custom-engineered and built cleaning and pumping systems based on our customer’s individual specifications and site-specific needs.

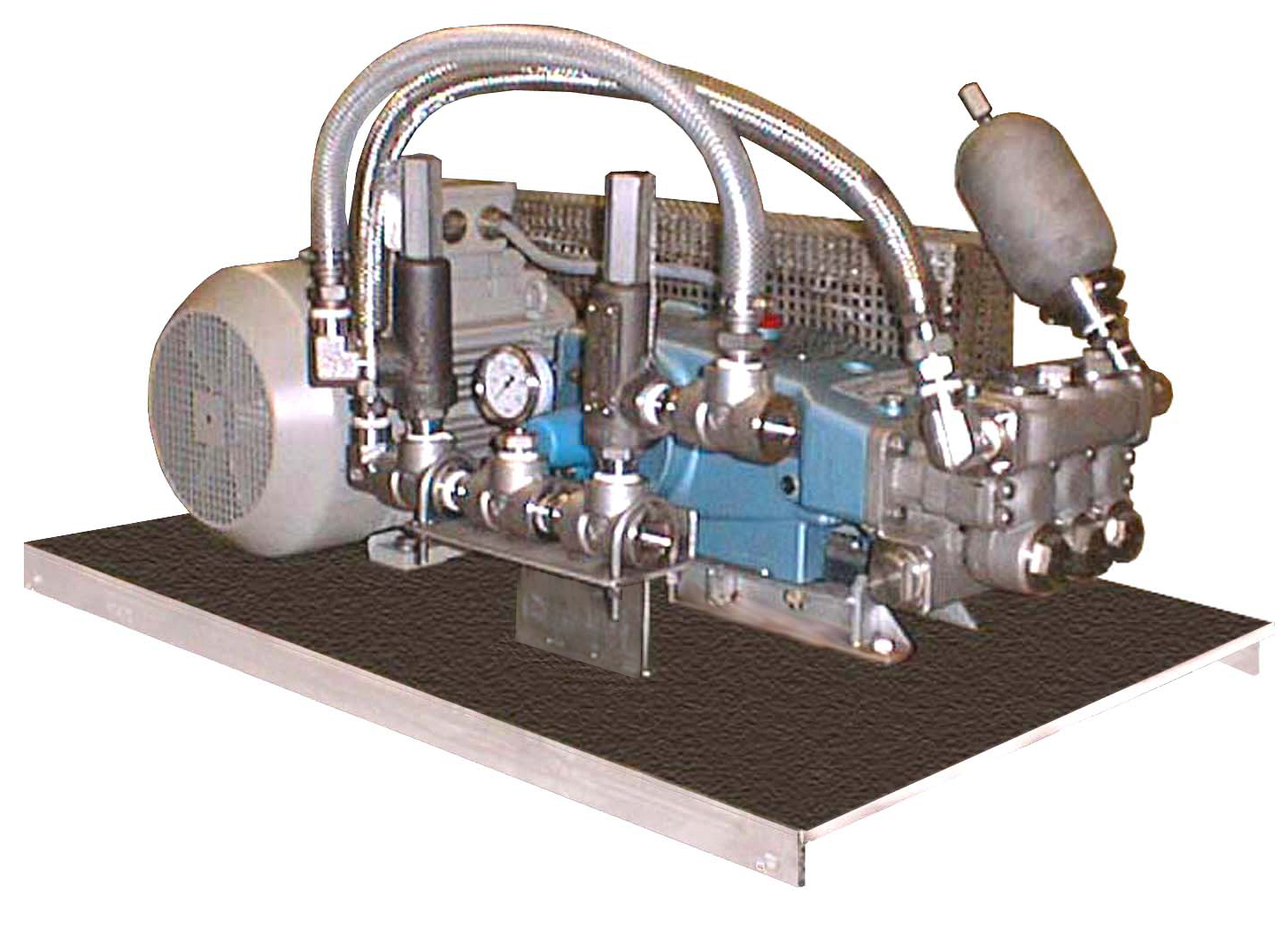

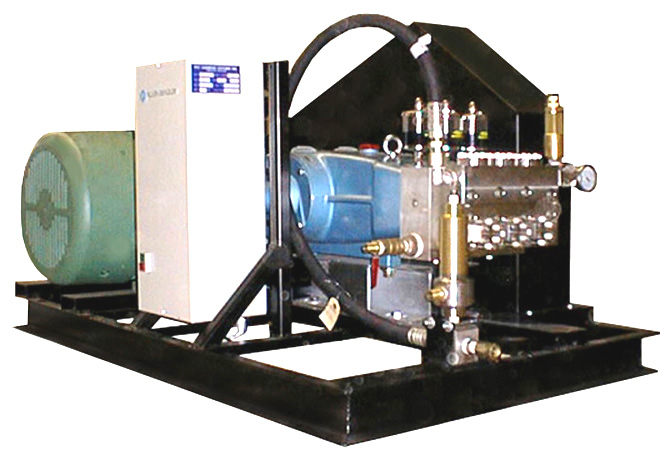

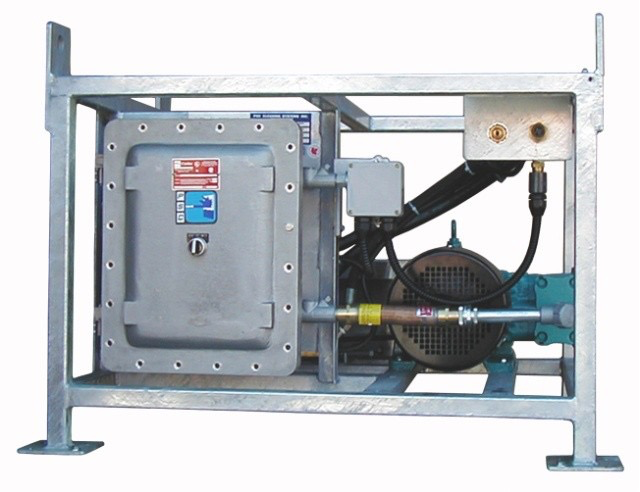

By integrating a range of pumps, tanks, and control systems, custom systems can be built to meet specific design and output requirements for virtually any low, medium or high pressure cleaning or pumping application.

If you think you have a unique application, let us design a unique system for you. Here are some of the interesting projects we have already tackled:

- Electrically heated aircraft de-icing systems for use on regional jets

- Air-driven and electric-driven pumping packages for high pressure injection and drill bit cooling in underground mining applications

- Integrated, variable volume pumping packages for use with water soluble cutting oil on CNC machines

- High volume, high pressure pumping packages for use on egg carton extrusion presses

- High pressure, low volume pumping packages utilizing hot and cold de-ionized water for automated printed circuit board cleaning systems

- High pressure systems for cleaning with heavy water in nuclear reactors

- High pressure, high volume pumping packages for de-watering in sewage treatment plants

- Automated pumping packages utilized in precooked shell fish cleaning systems

- Electrically heated systems for high pressure cleaning with peanut and vegetable oils in food grade applications