BELOW GROUND OIL WATER SEPARATOR GENERIC SPECIFICATIONS

PART 1 – GENERAL

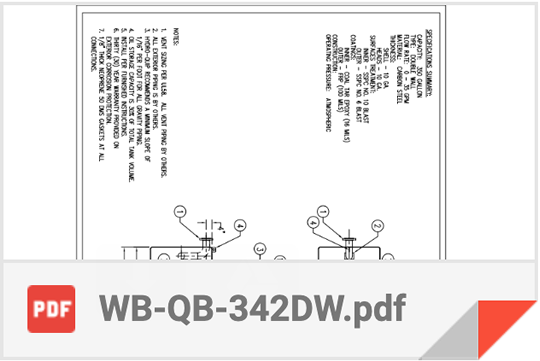

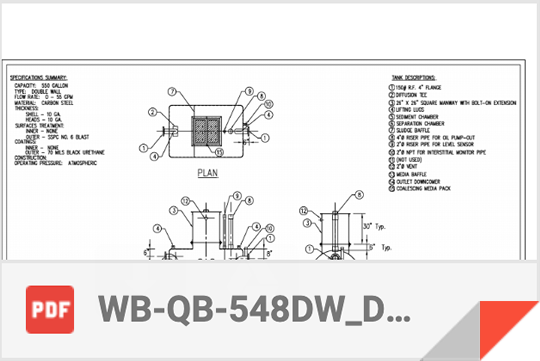

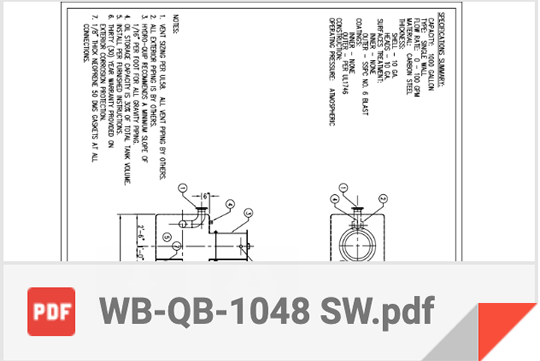

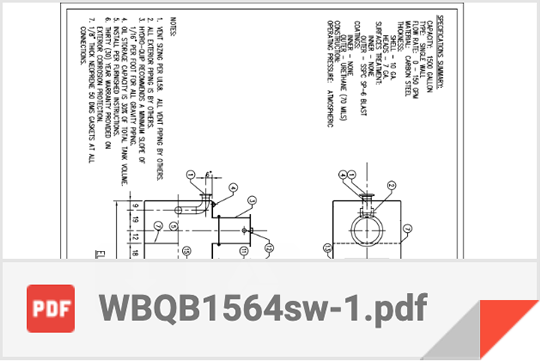

1.1 DESCRIPTION: The Wash Bay Solutions (WBS) oil/water separator Model WB-QB- __________ shall be a special purpose prefabricated parallel corrugated plate, cylindrical, gravity displacement, type double wall oil water separator, as specified herein. The separator capacities, dimensions and construction, shall be in strict accordance with UL 58 and UL 1746.

1.2 APPLICATION: The oil/water separator shall be designed for gravity separation of non-emulsified oil and some settleable solids from the wastewater stream. The separator is designed to receive oily water by gravity/pumped flow that will not mechanically emulsify the oil and will process it on a once through basis. The source of the influent to the separator shall be flow from___________ [describe the application or process].

1.3 PERFORMANCE: The oil/water separator shall remove essentially all free and dispersed non-emulsified oil from the water stream and produce an effluent containing less than ___ mg/l of oil droplets larger than ___ microns.

1.4 INFLUENT CHARACTERISTICS: The oil/water separator is designed for a maximum average flow of __ gallons per minute (gpm). The influent is further characterized as follows:

Operating Temperature ___ °F

Specific Gravity of Oil ___

Specific Gravity of Water 1.0

Specific Gravity of Solids ___

1.5 DESIGN CRITERIA: The oil/water separator shall be designed in accordance with Stokes Law and API Bulletin No. 421.

1.6 INSPECTION AND QUALITY ASSURANCE: The oil/water separator shall be fabricated, inspected and tested for leakage with 5 psi compressed air before shipment from the factory as a completely assembled system ready for installation.

1.7 SUBMITTALS: Shop drawings for separators shall be submitted and shall show principal dimensions and locations of all fittings. Design calculations shall be provided and shall reflect that oil/water separator is in conformance with effluent requirements when operating under detailed influent conditions. These calculations should show oil rise rate, overflow rate, Reynolds Number and removal efficiency. Shop drawings shall include brochures, catalog cuts, operations and maintenance instructions, dimensions, and location of accessories.

1.8 DESIGN DATA: An analysis shall be submitted which indicates that, at the calculated overflow rate, the separator will be provided with the required square feet of projected plate separation area to achieve the specified performance under laminar flow (i.e. Reynolds number of less than 500) conditions. Calculations shall take into account the rate of flow, influent concentrations, particle characteristics, fluid temperature, and fluid specific gravities.

PART 2 CONSTRUCTION

2.1 FABRICATION: The oil water separator is a special purpose prefabricated parallel corrugated plate, cylindrical, gravity displacement type, (__single wall __double type I, ___double wall type II) oil water separator. The separator capacities, dimensions and construction, shall be in strict accordance with UL 58 and UL 1746. The separator shall be comprised of a tank containing an inlet compartment, separation chamber, sludge chamber, oil storage chamber and clean water outlet chamber.

2.2 TANK: The tank shall be constructed of ___” minimum thick carbon steel pate conforming to ASTM A36. Welding will be in accordance with AWS D1.1 to provide a watertight tank that will not warp or deform under load.

2.3 FLANGES: All connections shall be flat face flanges with ANSI 150 pound standard bolt circle. Flanged piping connections shall conform to ANSI B16.5.

2.4 MANWAYS: The tank shall be provided with at least one manway to provide access into the separator to service the coalescer and sludge removal from grade level. The manway will be provided with an extension, clamp down cover and gasket.

2.5 LIFTING LUGS: The tank shall be provided with properly sized lifting lugs for handling and installation.

2.6 INDENTIFICATION PLATES: Identification plate should identify manufacturer, describe procedures for operating and servicing the equipment, and include warning of any hazardous conditions. Plates shall be durable and legible throughout the life of the equipment.

2.7 INLET COMPARTMENT: The inlet chamber shall be comprised of a non-clog diffuser to distribute the flow across the width of the separation chamber. The inlet compartment shall be of sufficient volume to effectively reduce influent suspended solids, dissipate energy and begin separation. The sludge baffle will be provided to retain settleable solids and sediment from entering the separation chamber.

2.8 SEPARATION CHAMBER AND MEDIA: The oil separation chamber shall contain the required amount of coalescing media that is sufficient for the removal of a minimum of 99.9% of free droplets __ micron in size or greater at the designed flow rate. The elements (plates) of the media shall be positioned to create an angle of repose of 90 degrees with respect to longitudinal axis of the plate corrugations and spaced not less than 3/16 inch apart for removal of free oil and settleable solids. Configuration used shall not promote solids buildup on plates, which would increase velocities to point of discharging an effluent of unacceptable quality. Laminar flow with a Reynolds Number of less than 500 at a maximum designed flow rate shall be maintained throughout the separator so as to prevent re-entrainment of oils with water. Flow through the coalescing media shall be crossflow perpendicular to the vertical media elements such that all of coalescing media is available for contact with the oily water.

2.9 SLUDGE CHAMBER: The sludge chamber shall be located prior to and under the coalescing compartment and shall provide an adequate volume for the settling of any solids. It shall also prevent any solids from entering the clean water chamber.

2.10 OIL STORAGE: The waste oil storage shall be an integral part of the separator, and have a capacity of 30% of the separator volume. Oil will be stored on the surface of the water and can be pumped away when the oil water interface reaches a predetermined depth.

2.11 CLEAN WATER CHAMBER: The tank shall be provided with a clean water chamber that allows the water to leave the separator by gravity flow through the clean water outlet port.

2.12 VENTS: The tank shall be provided with sufficient adequately sized vents for vent piping to atmosphere.

2.13 CORROSION PROTECTION SYSTEM: The control system shall be in accordance with UL 1746.

2.14 INTERIOR COATING: Interior surfaces shall be sandblasted in accordance with SSPC-SP10 and coated with coal tar epoxy.

PART 3 – EXECUTION

3.1 DELIVERY AND STORAGE: All materials delivered to site shall be inspected for damage. Materials shall be stored on site in enclosures or under protective coatings and adequately protected to prevent damage during periods of inclement weather, including subfreezing temperatures, precipitation, and high winds. All materials susceptible to deterioration by direct sunlight shall be stored under cover to avoid damage due to high temperatures. No materials shall be stored directly on the ground. If special precautions are required, prominent and legible instructions for such precautions shall be marked on the outside of equipment or it’s crating.

3.2 HANDLING: Handling and placing of coated steel tanks shall be done with care and in a manner that will minimize damage to the coating and will not reduce the protective effectiveness of the coating. Do not drag materials. The coated tanks shall be placed carefully in position with a minimum of handling. All damaged surfaces, which occur during these operations, shall be repaired at the expense of the Contractor.

3.3 INSTALLATION: The oil water separators shall be installed as shown on the drawings and in strict accordance with the manufacturer’s recommendations.

3.4 INSPECTION: Examine each component of separator for compliance with requirements as specified. This element of inspection shall encompass visual examinations and dimensional measurements. Noncompliance with specified requirements, or presence of one or more defects preventing or lessening maximum efficiency of separator operations, shall constitute cause for rejection.

3.5 PRETEST PROCEDURES: After separator has been leveled, hydrostatically test unit for four (4) hours by filling full with potable water, provided by Customer, with means of getting it from the nearest source by the Contractor. Acceptance criteria for this test is no leakage after four (4) hours.

3.6 TESTING: After the hydrostatic test has been successfully completed and unit has been properly connected to influent and effluent piping, the Contractor shall inject the influent oil/water mixture of ___ ppm into separator filled with potable water. After initial injection, the unit shall be operated for a minimum of ten tank volume changes prior to testing for contaminant removal.

3.7 TESTS FOR CONTAMINANTS: The Contractor shall test the effluent to ensure that it meets the required oil concentration levels. Tests shall be performed by an independent certified testing laboratory.

3.8 ANALYTICAL METHODS: Test and sample preservation methods for test contaminants shall be in accordance with the latest revision of EPA Methods for Chemical Analysis of Water and Wastes.

3.9 TEST REPORTS: Testing reports or Manufacturer’s Certificate of Performance Compliance shall be submitted. If testing indicates that the system does not meet design requirements, all corrective measures shall be taken as necessary to achieve design requirements.

PART 4 – WARRANTY

4.1 TANK: The oil/water separator tank shall be provided with a thirty (30) year warranty against external corrosion.

4.2 TREATMENT EQUIPMENT AND ACCESSORIES: All treatment equipment and accessories supplied as part of the oil/water separator system shall contain a one (1) year warranty for defective equipment.

PART 5 – REFERENCES

The publications listed below form a part of this specification to the extent referenced. The publications are referenced to in the text by basic designation only.

5.1 AMERICAN PETROLEUM INSTITUTE (API): API Publication 421, “Monographs on Refinery Environment Control – Management of Water Discharges, Design and Operation of Oil-Water Separators”.

5.2 AMERICAN WELDING SOCIETY (AWS) STANDARDS: D1.1-92 Structural Welding Code-Steel.

5.3 UNDERWRITERS LABORATIORIES, INC. (UL) PUBLICATION: UL 58 Standards for Safety – Steel Underground Tanks for Flammable and Combustible Liquids

5.4 UNDERWRITERS LABORATIORIES, INC. (UL) PUBLICATION: UL-1746 Standard for Corrosion Protection and secondary Containment for Composite and Jacketed

Tanks

5.5 AMERICAN SOCIETY FOR TESTING AND MATERIALS (ASTM) STANDARDS:

A36-93 Structural Steel

5.6 AMERICAN NATIONAL STANDARDS INSTITUTE (ANSI) STANDARDS: ANSI B16.5-88 Pipe Flanges and Flanged Fittings

5.7 EPA METHODS FOR CHEMICAL ANALYSIS OF WATER & WASTEWATER:

16th Edition (1985) – Section 503A

5.8 STEEL STRUCTURES PAINTING COUNCIL (SSPC) STANDARDS: SSPC-SP10 Near-White Blast Cleaning

5.9 NATIONAL ASSOCIATION OF CORROSION ENGINEERS (NACE) STANDARDS:

Standards for Interior and Exterior Surfaces