Foamers are chemical applicators that use compressed air to create thick foam that can be projected onto any surface. Foamers greatly improve the effectiveness of cleaners and disinfectants since they increase the surface dwell time and assure complete coverage. Using foam also reduces the over-application of chemical since you can see exactly where the chemical has been applied.

Foamer Applications

- Large Area Foam Cleaning

- Food & Beverage Processing

- Industrial

- Metal Processing

- Military

- Farming

- Paper Mills

- Odor Control

Foamers are available in a variety of configurations to suit large or small jobs. They can be used as a pre-wash, a post-wash disinfectant, or general wash in facilities where plumbed water is unavailable. In facilities without compressed air, foamers can use boosted water pressure, a venturi injection system and atmospheric air to create foam.

A range of foam volumes and throw distances are available. We can recommend the best model to use based on your application and desired coverage speed. Wall mount models include heavy-duty stainless steel mounting enclosures and portable models feature heavy-duty stainless steel carts.

Air Pump-Fed Foamers

These units are powered by compressed air and are designed for use in facilities where plumbed water pressure is unavailable, unreliable or lower than the 35 PSI required. An air-operated diaphragm pump, mounted inside a stainless steel enclosure, draws and pressurizes a ready-to-use chemical solution to produce foam and project it through the hose, wand and nozzle to any surface up to 15 feet. The portable model draws pre-diluted chemical from an integrated tank on a cart and the mounted model draws from a customer-supplied stationary tank.

Portable Features

- Rugged 1/2″ air-operated, double-diaphragm pump

- Lockable stainless steel pump enclosure

- Air inlet ball valve and regulator/filter

- Machined poly foamer body

- Integrated 20, 40 or 60 gallon poly chemical concentrate tank with strainer

- All stainless steel 4-wheel cart with integrated hose rack

- Non-marking tires w/SS swivel casters – (2) rigid and (2) swivel

- Single or dual hoses with Open Flow Wands

- Adjustable foam consistency (wet/dry)

Wall-Mounted Features

- Rugged 1/2″ air-operated, double-diaphragm pump

- Lockable stainless steel pump enclosure

- Air inlet ball valve and regulator/filter

- Machined poly foamer body

- 50′ discharge hose & stainless steel ball valve

- Stainless steel foam wand & fan nozzle

- Provides 8 minutes of foaming time per 20 gallons of solution

- Covers up to 500 sq ft (46.5 sq m) in 1 minute

- Adjustable foam consistency (wet/dry)

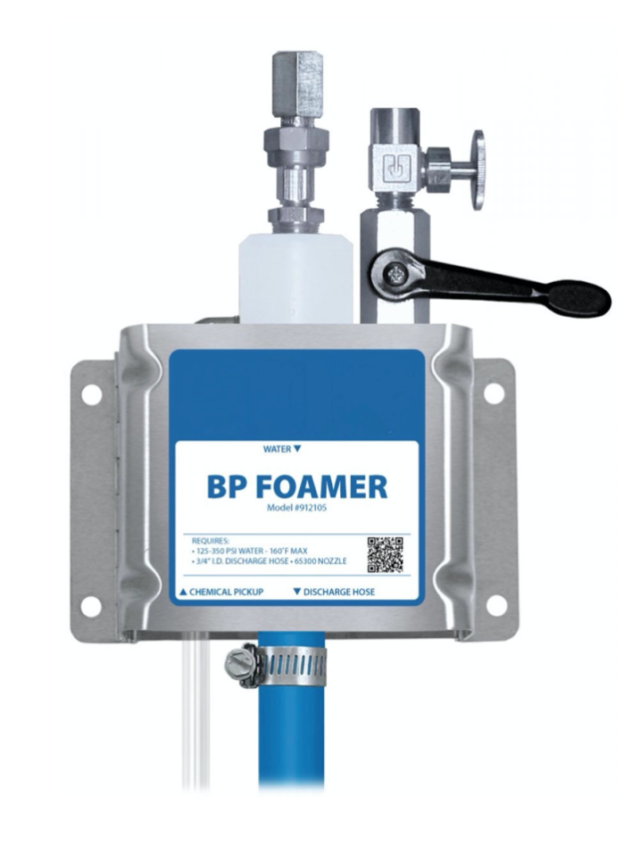

Boosted & High Water Pressure Venturi Foamers

These water-driven venturi injection systems use boosted water pressure (125-350 psi), high water pressure (400-1000 psi) or a pressure washer to draw and blend chemical concentrate from a tank into the water stream to create an accurately diluted solution. Air is injected into the solution to create the foam which is then projected through the nozzle onto surfaces at distances from 15 to 45 feet. The portable model draws pre-diluted chemical from an integrated tank on a cart and the mounted model draws from a customer-supplied stationary tank.

Portable Features

- Stainless steel 4-wheel cart with non-marking tires

- Two stainless steel swivel casters

- 20 or 60 gallon, wide-mouth, polyethylene chemical tank with drain

- Stainless steel water inlet ball valve

- Machined poly or stainless steel foamer body

- 20 color-coded precision metering tips to set dilution ratios

- 50’ discharge hose

- Poly or stainless steel foam wand

- Fan pattern nozzle for broad coverage

- Zero degree nozzle for high or distant coverage

- Adjustable foam consistency (wet/dry

- Available with other options

Wall-Mounted Features

- Stainless steel mounting bracket

- Machined poly or stainless steel foamer body

- 20 color-coded precision metering tips to set dilution ratios

- 50’ discharge hose

- Poly or stainless steel foam wand

- Fan pattern nozzle for broad coverage

- Zero degree nozzle for high or distant coverage

- Adjustable foam consistency (wet/dry)

- Available with ability to apply 2 chemicals at the same time

High Pressure Airless Foamers

Our Airless Foamers are medium to high volume foam applicators for projecting foaming chemicals without compressed air. Just attach it to a wall and connect it to a water source. These systems use venturi injection and boosted water pressure to draw and blend chemical concentrate into the water stream to create an accurately diluted solution. The solution then flows through the discharge hose and trigger gun to the “airless” foam wand that draws in atmospheric air to create foam. The foam can be projected on to any surface at distances up to 12 feet (depending on water pressure and nozzle).

Portable Features

- Uses boosted water pressure – HP (400-1000 psi)

- No compressed air required

- Designed for foam cleaning medium to large sized areas

- Stainless steel cart with stainless steel bucket strap, integrated hose rack and non-marking tires

- Stainless steel inlet ball valve

- Machined stainless steel or poly injector body

- 20 color-coded precision metering tips to set dilution ratios

- Discharge hose and trigger gun

- Stainless steel airless foam wand

Wall-Mounted Features

- Uses boosted water pressure – HP (400-1000 psi)

- No compressed air required

- Designed for foam cleaning medium to large sized areas

- Stainless steel inlet ball valve

- Machined stainless steel or poly injector body

- 20 color-coded precision metering tips to set dilution ratios

- Discharge hose and trigger gun

- Stainless steel airless foam wand