For clients who have to leak test vehicles to ensure that there has been no water intrusion after manufacturing or modifications, we have developed a complete leak testing system. Custom engineered to fit your facility and testing protocols, our water intrusion / leak testing systems consist of containment pads, test arches, a water supply system and a fully automated filtration system designed to remove contaminants from the test water so that it can be re-used for a period of time prior to disposal or discharge to the sewer. Designed for commercial and industrial applications, all features of the system are manufactured to insure superior performance and minimal operating requirements.

The containment system consists of a water containment pad constructed of steel or heavy-duty PVC.

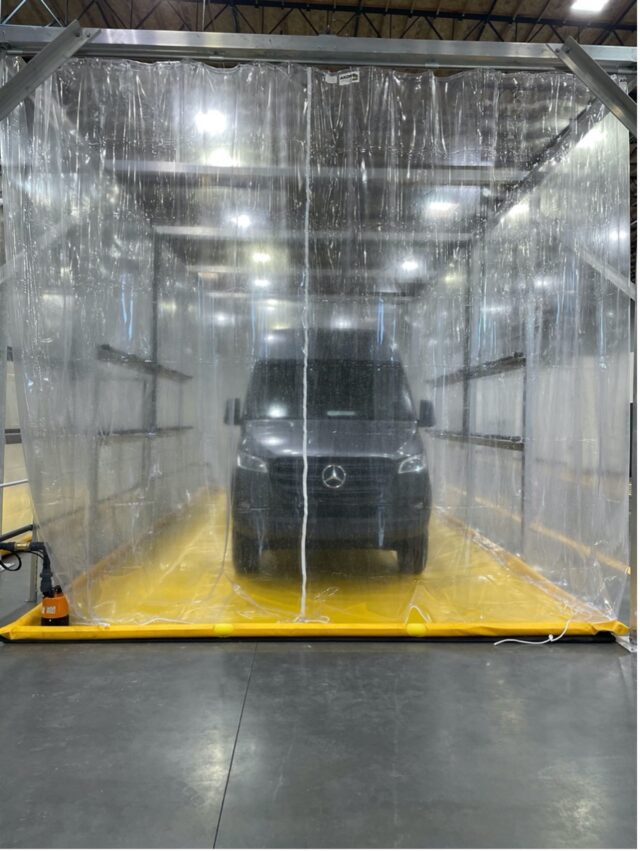

Sized to fit your facility and test vehicle, these pads feature entrance and exit ramps and drive over and/or pedestrian grating, if desired. Custom-sized water-proof canvas canopies, PVC curtains or Fiberglass walls are installed on the pad to minimize overspray.

The leak test system is built to fit into the containment system so there is no overflow. Depending on the client’s needs, the leak test system will include multiple side and overhead spray arches, vertical spray posts, and undercarriage spray bars, positioned to provide optimal coverage. The spray test will last for a client-specified period of time and can be easily controlled by a driver with a remote start/stop key fob.

During the water intrusion / leak test, water is automatically pumped from the containment pad through an initial filter to remove any minor solids and contamination. From there, water is pumped into manifolded water management tanks. The tanks provide enough water storage to permit proper water balancing during the testing period and the water recovery time. The tank system is equipped with level switches to protect the pumps and to automatically provide for fresh water make-up due to evaporation or drive-off losses. From these tanks, water is pumped back to the test arches, when needed.

In most leak test applications, the contaminants are minimal so this pumping and filtration cycle can last a considerable amount of time. When the water becomes too contaminated to re-use, however, the water can be pumped out or processed through additional filtration and discharged to the sewer.

Containment Pad with Canopy/Walls –

- Either fiberglass covered steel or HD PVC containment basins

- Entrance & exit ramps

- Drive-over, galvanized grating, installed with supports

- Water-proof canvas canopy, PVC curtains or Fiberglass walls with supports

Leak Test System – designed for installation in containment pad

- Spray arches with PVC piping and Aluminum frames

- Entrance/Exit Spray posts with PVC piping and Aluminum frames

- Undercarriage spray floor spray bar with PVC piping

- Stainless steel fixed nozzles installed in PVC piping

Pumping & Treatment System- designed for installation adjacent to containment pad

- Typically 60 GPM Flow rate @ 40 psi – can be higher or lower to client specifications

- Non-Ferrous Construction – Stainless Steel, PVC

- Fully-Automatic, pre-wired, pre-plumbed

- UL listed custom control panel with relays and valves and level switches

- Remote start and stop, field adjustable run time

- Multiple water storage tanks with level sensors to receive water from basin

- Fresh-water make-up system to keep tanks filled

- Multiple pumps to circulate water from pad to arches and filtration system

- Initial filter system to catch particulate

Additional Options

- Final filtration system

- Oil water separator

- Spot free rinse

- Containerized equipment room