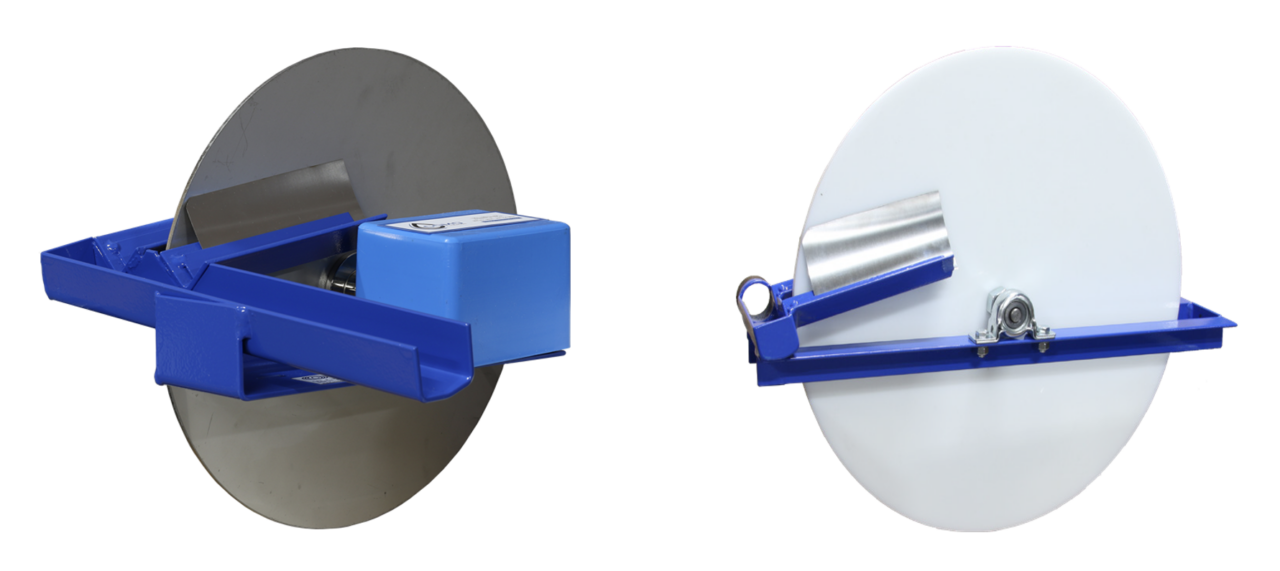

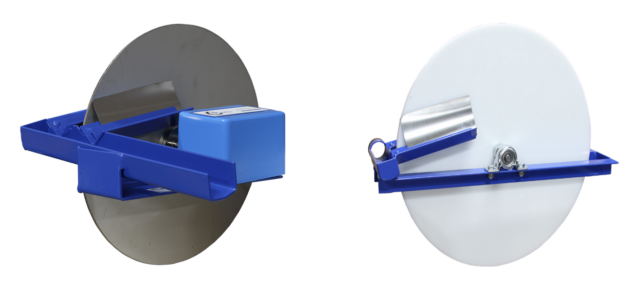

One of the most effective ways to remove floating oils from an oil water separator is with an electric 12” disk skimmer. Mounted on the side of the clarifier and/or coalescing compartments, the skimmer assembly consists of an oleophilic wheel that slowly rotates so that oils and sludge adhere to the wheel’s surface. A spring-loaded blade wipes the oil from surface of the wheel and discharges the oil into a steel trough connected to the oil storage tank.

The 115V disk skimmer motor is controlled by a simple control panel with a field-adjustable timer so that you can remove floating oils as often as necessary for your particular application.

Standard Features

- Front- or side-discharge trough

- High temp stainless-steel skimmer wheel for fluids up to 180°F

- 12-18-inch HDPE skimmer wheel for fluids up to 140°F

- 12-18-inch stainless-steel skimmer wheel for fluids up to 180°F

- 115 Volt, 7 RPM, shaded-pole motor & gear assembly

- Control with field adjustable timer

- Powder-coated skimmer frame and discharge trough

- Approximate dimensions: 14” W x 8” D x 12” H

- Approximate weight: 14