We offer a complete line of high efficiency, stainless steel above ground oil water separators that will remove nearly all free and dispersed non-emulsified oil and settleable solids from the waste stream.

oily water separator

Our new solids settling below ground separator is ideal for any application with high concentration of solids and oil in water.

Most old conventional separators require long retention times, resulting in needlessly large units. They also have little in the way of solids settling. Our new innovative new design has both a much smaller footprint and a much higher removal efficiency for both oil and solids which lowers your total cost of ownership.

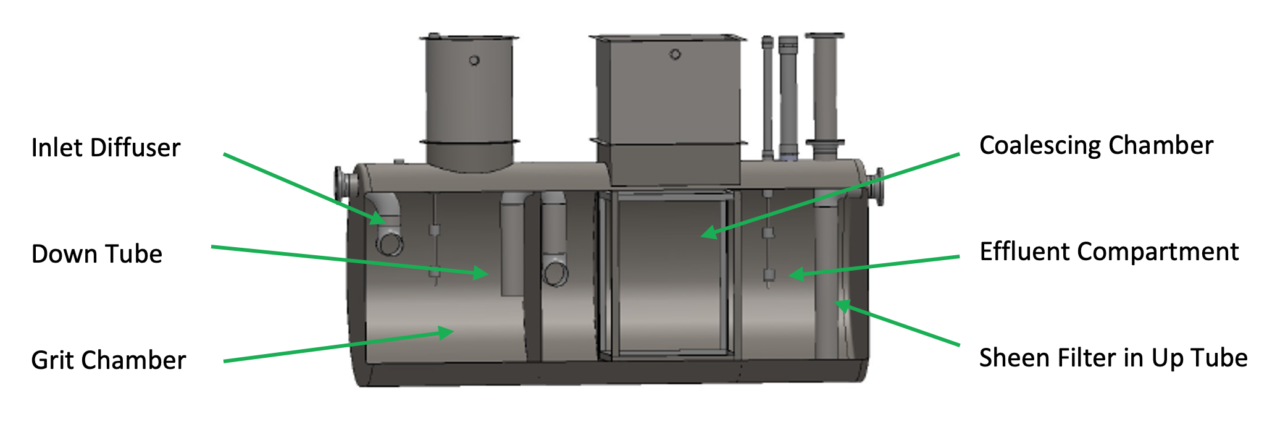

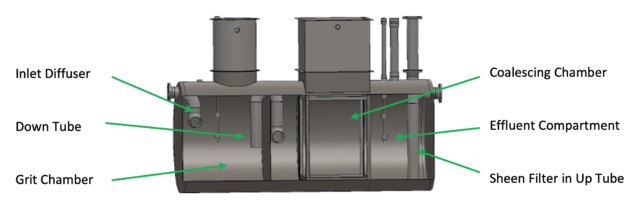

How it works:

To enhance separation, these separators contain an inlet diffuser, grit chamber/inlet compartment, down tube, coalescing/separation chamber, oil storage area, effluent compartment, and sheen filter.

- In the Grit Chamber, the inlet diffusor initially distributes the incoming water flow evenly over the cross-sectional area of the separator. The free oil (150 micron size or larger) is separated and the settleable solids are captured at the bottom.

- The suspended solids and dispersed oil then flow upward through the down tube in the Grit Chamber, and over to another diffusor in the Coalescing Chamber.

- The flow continues through the Coalescing Chamber where the coalescing plates will separate the oil droplets 30 micron size and larger up to the surface, and the remaining suspended solids will be captured beneath the coalescing plates.

- Finally, a removable Sheen Filter inside the up tube in the Effluent Compartment will remove carryover, smaller droplets of oil, and mechanical emulsions.

Performance Standards

- Utilizes patented, revolutionary, non- plugging coalescing plates which remove free oil droplets as small as 30 microns

- Performance guarantee based on influent characteristics

- Will achieve discharge of 5 ppm or less in accordance with CEN EN 858-1

- Warranted for (1) year on material and workmanship and (10) years against external corrosion

Below Ground Oil Water Separator Models

| Model # | Average Flow Rate (GPM) | Capacity

(Gallons) |

Inlet/Outlet (Inches) | Dimensions, D x L (Feet) |

| WB-QB-35-ES | 35 | 350 | 4 | 3.5 X 6 |

| WB-QB-55-ES | 55 | 550 | 4 | 4 X 6 |

| WB-QB-100-ES | 100 | 1000 | 6 | 4 X 10.75 |

| WB-QB-200-ES | 200 | 2000 | 6 | 5.3 X 12 |

| WB-QB-300-ES | 300 | 2500 | 6 | 5.3 X 15 |

| WB-QB-400-ES | 400 | 3000 | 8 | 5.3 X 18 |

| WB-QB-500-ES | 500 | 3800 | 8 | 6 x 17.5 |

| WB-QB-600-ES | 600 | 4000 | 10 | 6 x 18.75 |

| WB-QB-700-ES | 700 | 7000 | 10 | 8 X 18.67 |

| WB-QB-800-ES | 800 | 7000 | 10 | 8 X 18.67 |

| WB-QB-900-ES | 900 | 7000 | 12 | 8 X 18.67 |

| WB-QB-1000-ES | 1000 | 7500 | 12 | 8 X 20 |

| WB-QB-2000-ES | 1200 | 8500 | 12 | 8 X 22.5 |

| WB-QB-1500-ES | 1500 | 12000 | 16 | 10 X 20.75 |

| WB-QB-2000-ES | 2000 | 14000 | 18 | 10 X 24 |

| WB-QB-2500-ES | 2500 | 17000 | 18 | 10.5 X 26.5 |

| WB-QB-3000-ES | 3000 | 19000 | 20 | 10.5 X 29 |

Call Now to Speak with a Oil Water Separator Specialists – 1-800-453-8639!

“Our washing operation used to dump 3,000 to 5,000 gallons of process water down the sewer each day because it was contaminated with petroleum oil and wax. Not only did we lose this water in the middle of the worst drought in history but the heat energy it contained as well. We also risked plugging up the city sewer system.

With the help of Wash Bay Solutions, we designed a system using a floating oil skimmer on a hose, a non-emulsifying air pump, and a coalescing stainless steel oil water separator.

The system removes the floating oils from the top of the water surface and directs the water continuously into the oil water separator. The unit produces water so clean that we can use it in our boilers and cooling towers. Zero water is now sent down the sewer.”

John

California